Tool/software:

Hi,

I'm trying to understand how to go about calculating

the worst cases error calculation in current sensing reading

Here's the schematic:

Regards

Jonathan Kabangu,

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Tool/software:

Hi,

I'm trying to understand how to go about calculating

the worst cases error calculation in current sensing reading

Here's the schematic:

Regards

Jonathan Kabangu,

Hello Jonathan,

Here is a link to a TIPL video series that has a section for learning about different error sources:

https://www.ti.com/video/series/precision-labs/ti-precision-labs-current-sense-amplifiers.html

For a worst case error, you could add the error from all sources together, but a more realistic way to add the errors would be to use RSS error. Here is a link to a calculator tool that uses RSS error to estimate total error:

https://www.ti.com/tool/download/CS-AMPLIFIER-ERROR-TOOL

This tool does not include all possible errors, such as errors from your input filter, but it does have a description of which errors it does use.

Also, I see in your schematic that you have capacitors to GND on the IN+ and IN- pins. This is generally fine to do if your Common Mode voltage is not changing much, but can cause errors if you Common Mode is changing. Here is a link to an E2E and App Note that have more info on this:

https://www.ti.com/lit/ug/slya042/slya042.pdf

Regards,

Mitch

Hi,

1.I downloaded the tool

but it does seem to be working well for me

any guidance on this

2.which input filter is this?

3.Can you explain more on common mode voltage change please

Regards

Jonathan Kabangu

Hey Jonathan,

Here are my responses to your questions:

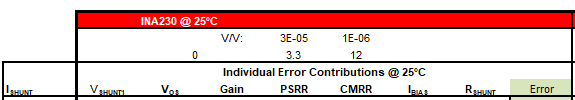

1. For the error tool to work, you need to select your device in the yellow box:

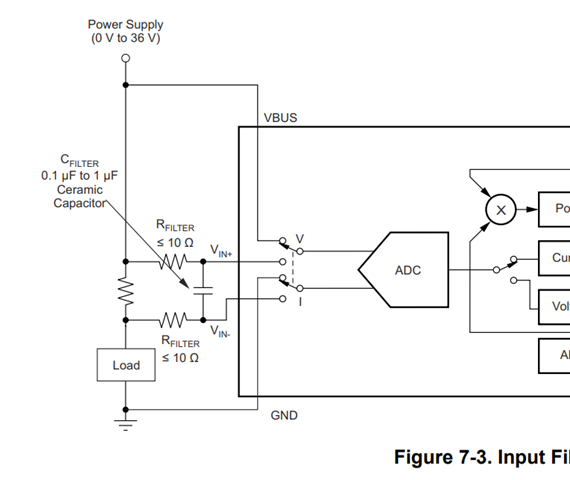

2. This is the input filter:

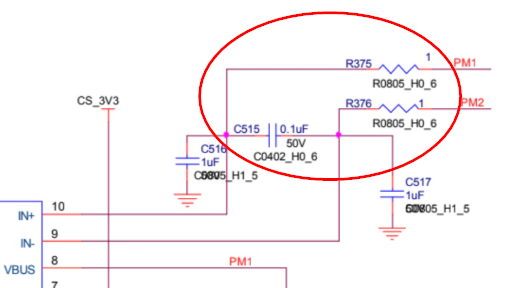

which from your schematic is:

3. The links I provided explain in more detail, but if you have an AC signal or anything that is causing the voltage at IN+ and IN- to change often, then any mismatch in C516 and C517 will cause error. If you are measuring DC or have a more constant voltage, then those capacitors are fine.

Regards,

Mitch

Hi Mitch,

1.

The error is returning "VALUE!",any reason why?,and the reason is not showing much aswell

2.Thanks for the explanation

3.in our system we're monitoring Bus voltage coming from car battery

Regards

Jonathan Kabangu

Hello Jonathan,

From your screenshot, on the left the "Supply Voltage Range" box is highlighted bright red with yellow text to match the warning. This means that the value you put in for Supply Voltage is out of range. (You have 30V in the box for supply, but the acceptable range is 2.7V-5.5V). As a side note, you can also change the x-axis of the plot by either double clicking, or right clicking and going to axis options. This way you can set the max current drawn to 2A to better show your desired range.

Regards,

Mitch

Hi Mitch,

the tool worked!

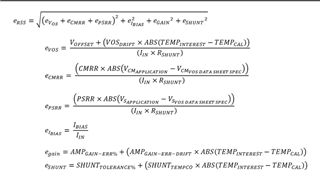

i wanted to breakdown this formulae:

Thanks

Jonathan Kabangu

Hello Jonathan,

Here are my responses to your questions:

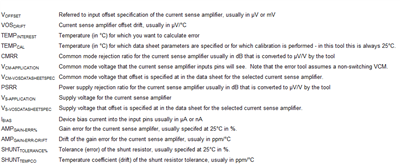

1. All of the "e" error values are in percent. The rest of the variables are defined in the "Help" tab of the error tool:

And the equations to error (e) are shown in the screenshot you attached (also on the "Help" tab of the tool).

2. The "Help" tab of the tool says:

3. To manually calculate this, you can just put in all the values defined in question 1 into the equations you showed in your question. If you want to validate individual calculations, then you can scroll to the right of the error plot in the tool, and it will show you the individual error components:

Then you can scroll down to the 2A section to see the individual calculations for the 2A case.

Regards,

Mitch