Other Parts Discussed in Thread: LM239

Tool/software:

Hi everyone,

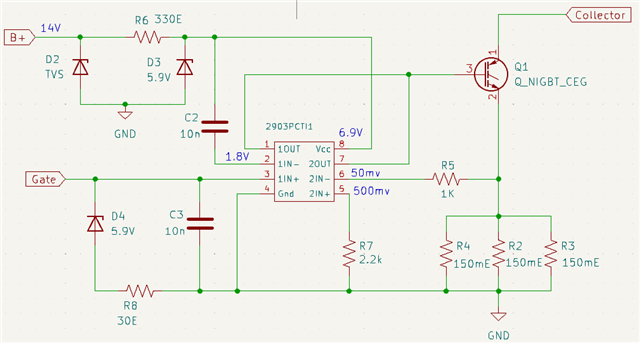

I recently bench marked a schematic used in a car ignition coil driver.

-

B+ → battery supply

-

Gate → input pulse from ECU

-

Collector → connected to ignition coil

The circuit works fine in the car, but I’m trying to fully understand how it operates.

The controller IC has the body marking “2903_PCTI1.” Since it mentions 2903, I assumed it might be similar to an LM2903 dual comparator. However, I’m not certain if it really is a comparator, or how exactly it’s being configured in this circuit.

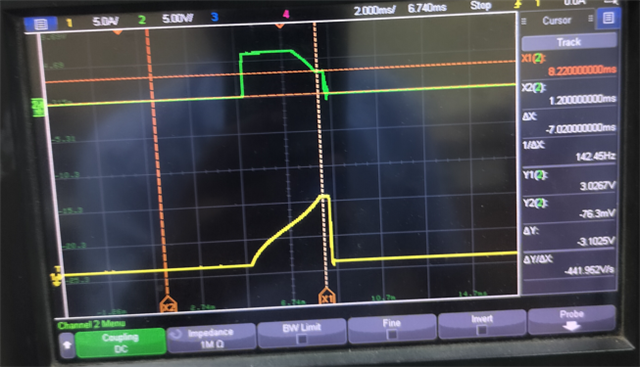

Here’s what I observed during testing:

-

Under normal operation, the output signal follows the ECU’s gate signal, but the amplitude is limited to ~6 V.

-

Once the ignition coil current (collector–emitter) reaches around 10 A, measured through a shunt resistor, the output amplitude gets clamped to ~3.3 V (waveform attached). CH2-Gate I/P to IGBT, CH1-Collector Current

-

I’m not sure how the circuit is implementing this amplitude limiting/clamping function.

If anyone can help me understand how this configuration works, it would really help me design a more optimized version for the same application.