Hi TI Support Team,

I would like to request your assistance and clarification regarding a recent fresh yield issue observed on the TL074CDR operational amplifier, where we observe burn mark on the VCC Pin (V+,Pin 4) of the part (DC2443) after performing regular functional testing. The module passes after reworking with other date code. Some units didn’t reveal the sign of burnt but causing the power missing on module level functional test and show the abnormal sign of IV Curve Test. No changes in testing, layout, components, process, environment. We are encountering FCT self-test failures on product affecting 20% failure rate PCAs and 100% pass on DC 2327 and 2332 (Last good DC). There are 3 units per board and only U4 with rejects.

As a proactive measure, Our CM has done internal FA with the following initial conclusion. After troubleshooting, we isolated the root cause corresponds to TL074CDR :

Location : U4, U1 & U728

Date Code : (Good DC 2332, 2312 & 2327 vs Bad 2443, 2436 & 2522)

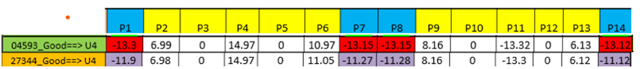

Based on the recent findings, there is an obvious difference between the older date code and the latest failing date code.

The output voltage (P1/P7/P8/P14) of the new Date Code parts(highlighted in red) rails to maximum of the negative VCC (-13V) supply unlike the older once (highlighted in purple) where it is 1 V lesser (-11.5v)

It happens to all the 3pc of the IC that is used in the PCA. (no load condition)

For more details kindly refer to FA Req No : CPR251132476

Thus, may I know, how does this difference can lead to this issue ?