Hi, we have implemented a strain gauge to 4-20mA converter using the XTR117 and are seeing more failures in the field than we are happy with.

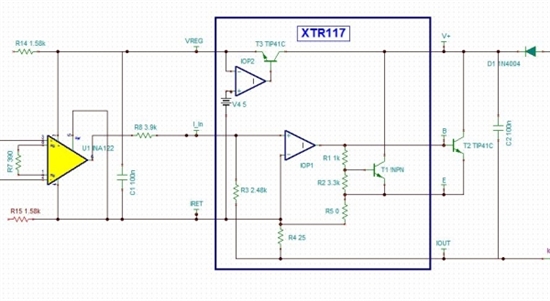

The circuit uses an INA122 instrument amp to amplify the strain gauge signal and the rest of the circuit is as per figure 1 of the datasheet (external transistor, and a series diode for reverse polarity protection). series resistors limit the sensor bridge current to about 1.3mA

The observed symptom is 0V from VREG. With the rest of the IC functioning normally.

In our bench testing, we observe that the VREG output is quite robust and tolerates short circuits.. Actually, in our bench testing, we are unable to get the devices to fail at all..

Could a voltage transient on the supply cause this fault?

Thanks

PK