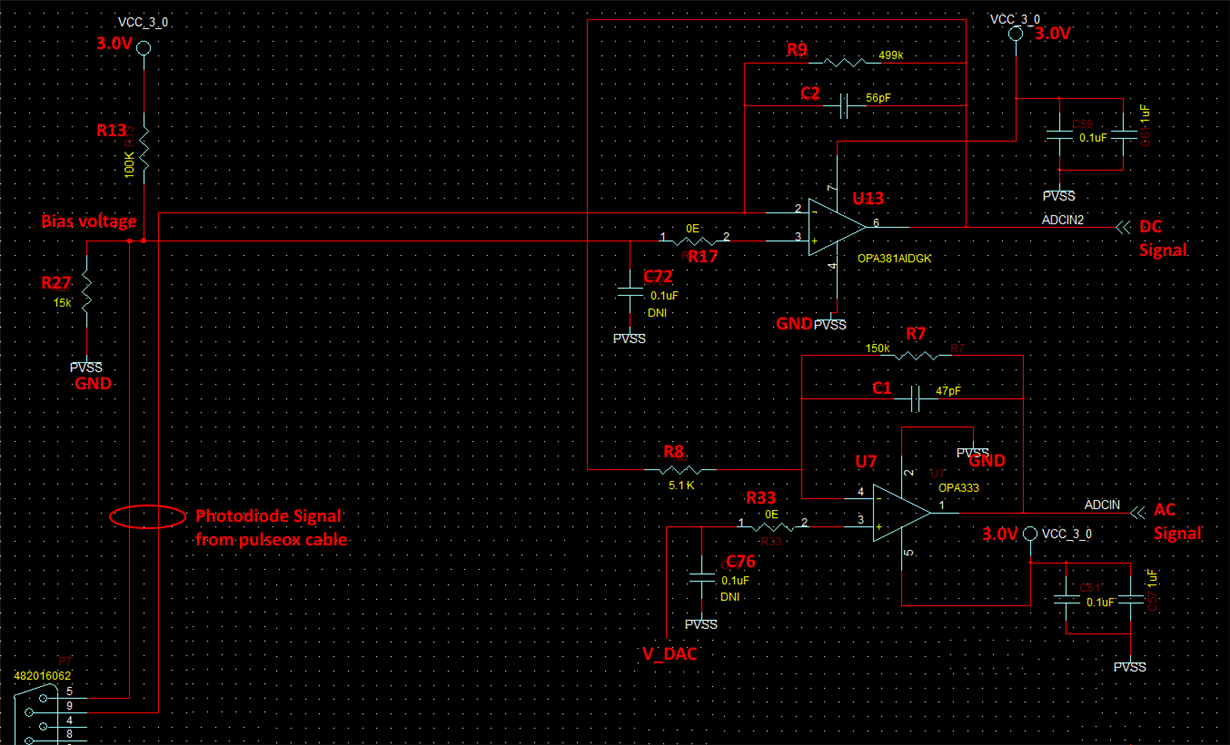

We are having a problem with line noise with our pulse oximeter circuit, which is based on a TI reference design. We want to modify the circuit to eliminate this sensitivity and we are seeking advice on the circuit shown here:

We had noted a line noise problem in our prototype and thought it would be improved in the layout for our final board. We were advised by a TI engineer to add pads for C72 and R17 on non-inverting input of stage 1 and pads for C76 and R33 on non-inverting input of stage 2. This was done so that we could fix the noise problem if it persisted. Well, it did persist and I don't have the name of the original engineer that made this suggestion so I am posting here for advice.

An optimal solution for us would be populating C72 and/or changing the zero ohm jumper at R17, but I am guessing we may have to decrease the bandwidth of the TIA by changing C2 and or R9 (not optimal as component removal step is involved). I suppose there could even be a problem with the biasing of provided by the R13/R27 voltage divider of about 0.39V.

We were also working on modeling this circuit on LTSpice, but it appears it would be wiser to go with TINA as we would have access to the OP333 and OP381 models. If we must do a simulation then we would also need advice on simulating the photodiode (we have the spec sheet from the mfg of the cable, but no model for the photodiode itself).

Thanks in advance for your help and kind advice,

Kevin

PS: The new product is using the AFE4400, which was still in beta when this design was done