Other Parts Discussed in Thread: OPA192

Hi

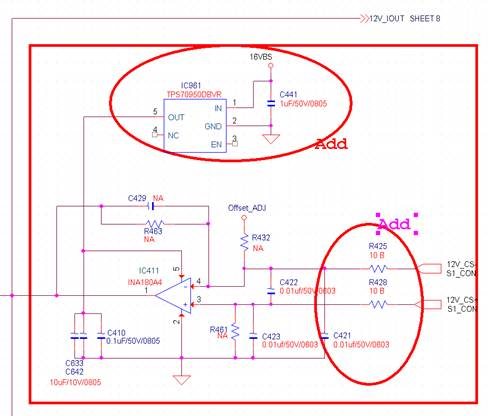

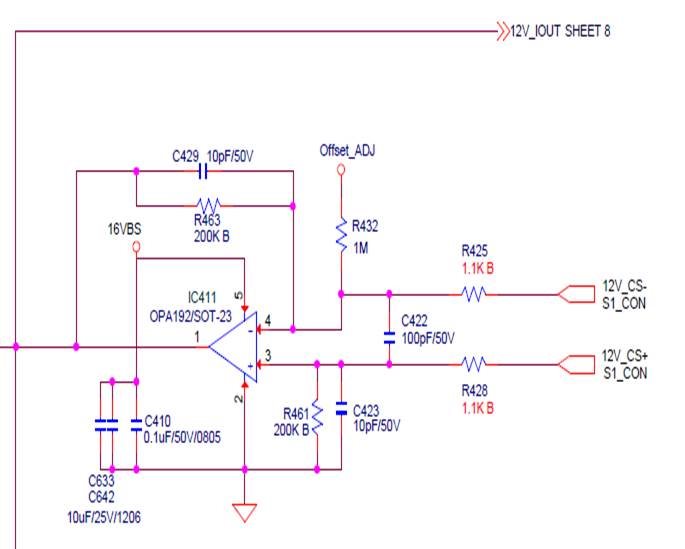

Our customer is using our INA180 as current sense at server PSU. The common mode voltage is 12V. Power supply is 16V-GND;So far we found the static and dynamic issue at test:

1. Static error: The INA180 output will go to MCU A/D port;

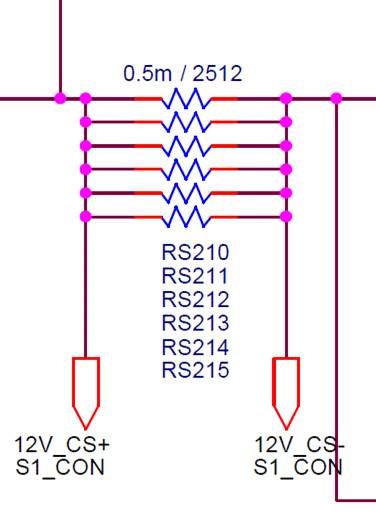

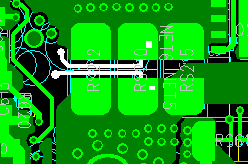

Kelvin type layout:

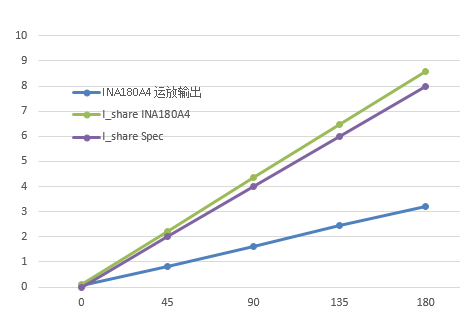

But we found the static output is below:

There is a little bit tolerance between I_share INA180A4(real value) and I_share Spec(ideal value). I just recommended our customer Calibrate and correct by using the software. Do you have any suggestion about the error?

2. Dynamic output:

This server PSU output needs support high frequency load transient: 3A-111A at 10kHz

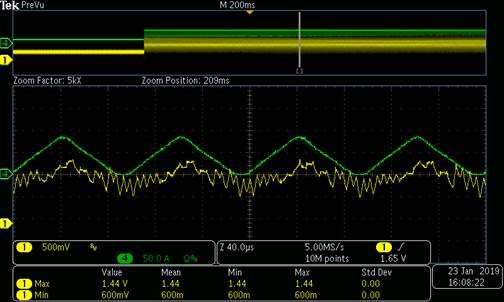

The test result is below: CH4: Output current(3A-111A); CH1: INA180A4 output C422 = 100Pf, C423 = C421 = 1000pf

So here you can see the amplifier output will go to unstable oscillation. Do you have any suggestion about this unstable situation?

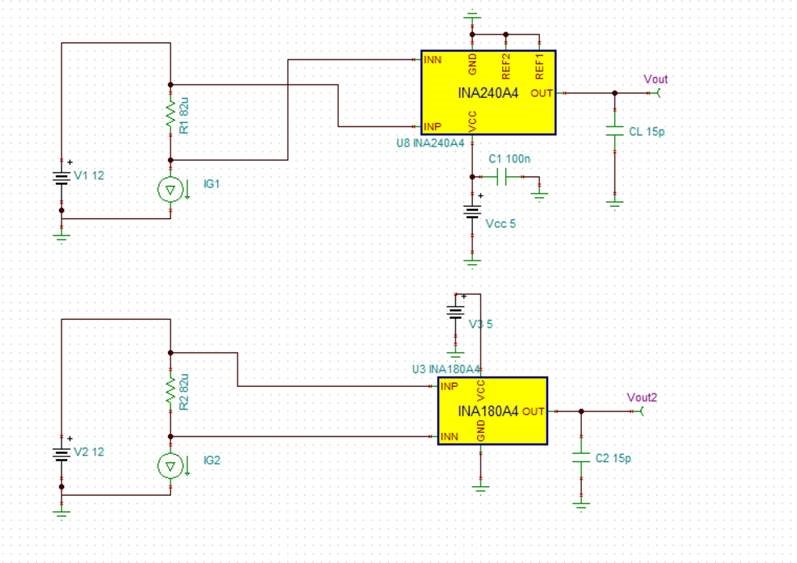

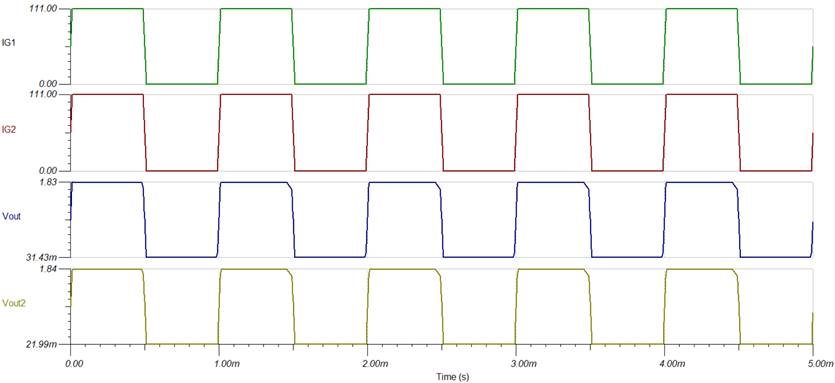

I also did some simulation about out part at this load transient condition: 3A-111A 10KHz:

I didn't find any unstable issue here. So I can't understand what can lead our part to this issue. The input common mode cap and differential mode capacitor?

Any feedback are appreciated. Very urgent case.

Thanks

-Pengfei