Part Number: LM397

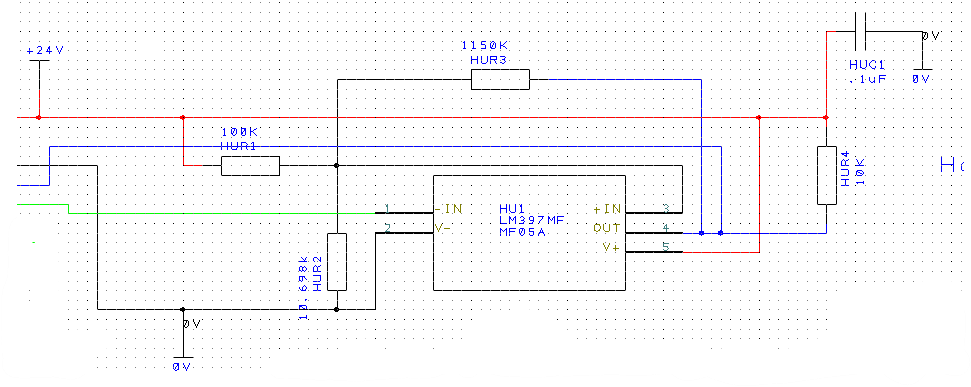

I want to deploy 12 LM397 Voltage comparators onto one PCB board, and TI recommends decoupling capacitor for the power supply. I want to confirm if the capacitors are needed individually for each LM397 or a single capacitor can do the job for the whole board? You can see part of my circuit in the attached picture. I have the comparators set up for hysteresis with a 24Vsupply, a pull up resistor, a resistor network for hysteresis, a capacitor between the inputs to further eliminate oscillations in the transition region, and decoupling capacitors for the power supply noise. The capacitors in question are C1 and C4.

I'm thinking I only need one because having multiple will put the capacitors in parallel and create a larger capacitance than desired, but I am a little unsure ?