Hi,

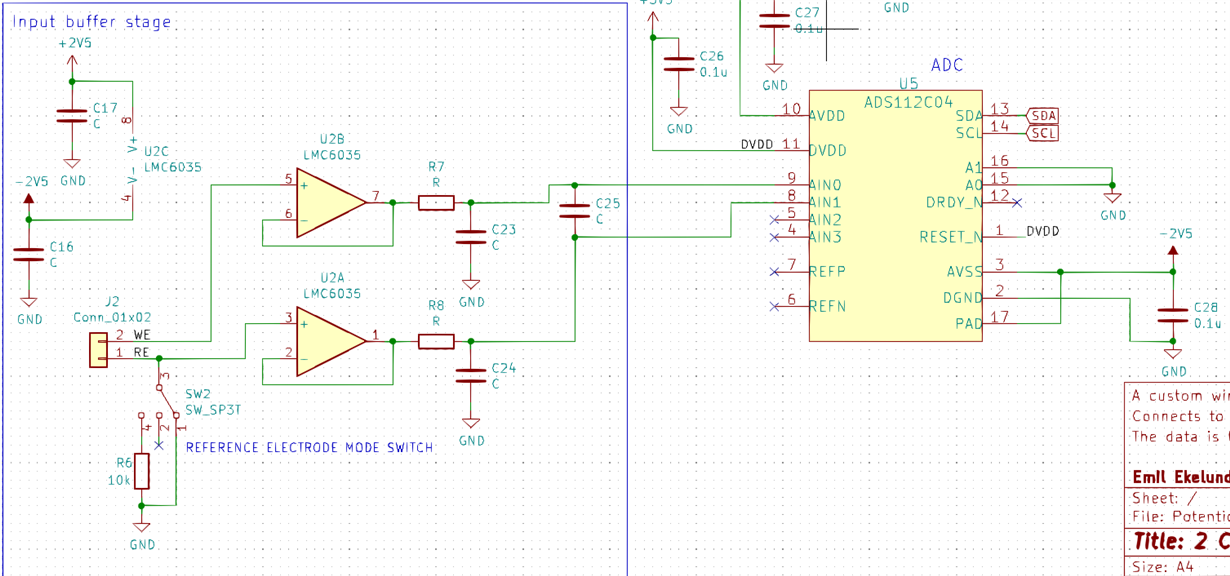

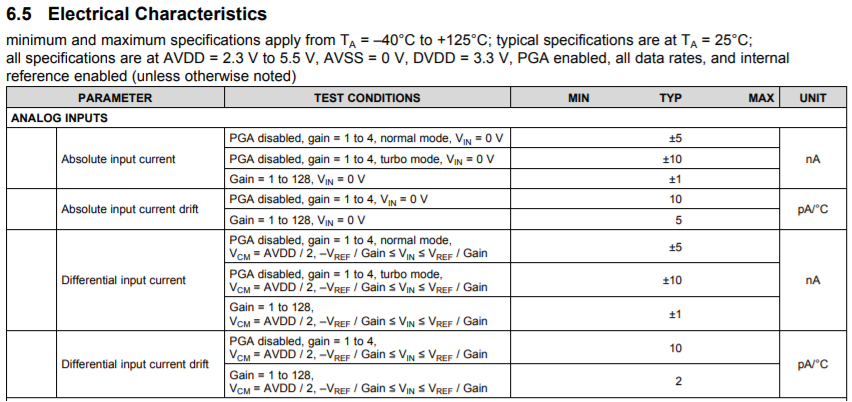

I am doing measurements with my own electrochemical pH sensor and need a buffer for two electrodes, one reference and one working electrode. The higher impedance the better essentially. At my disposal as supplies I have +3.3V and ±2.5V.

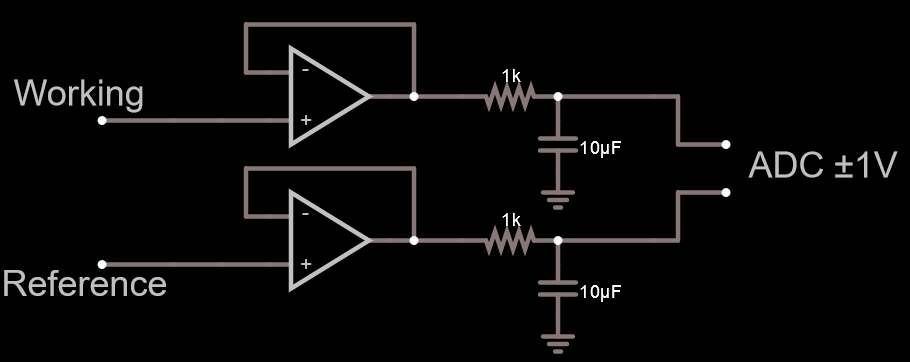

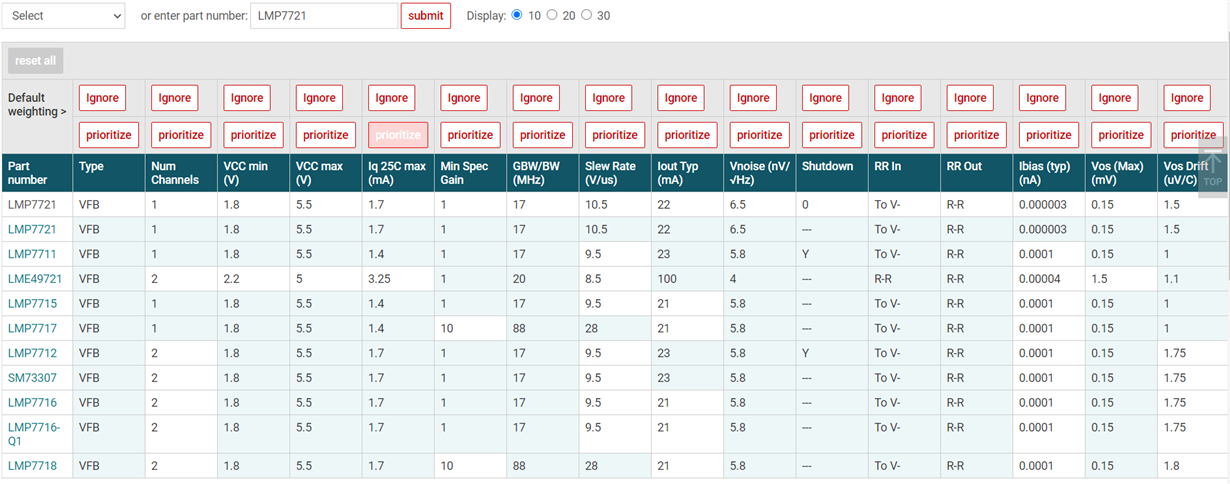

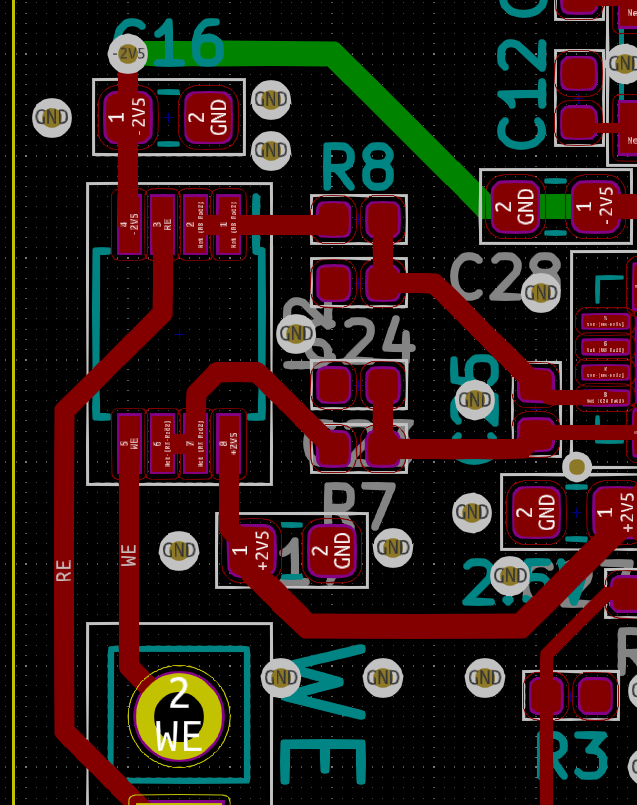

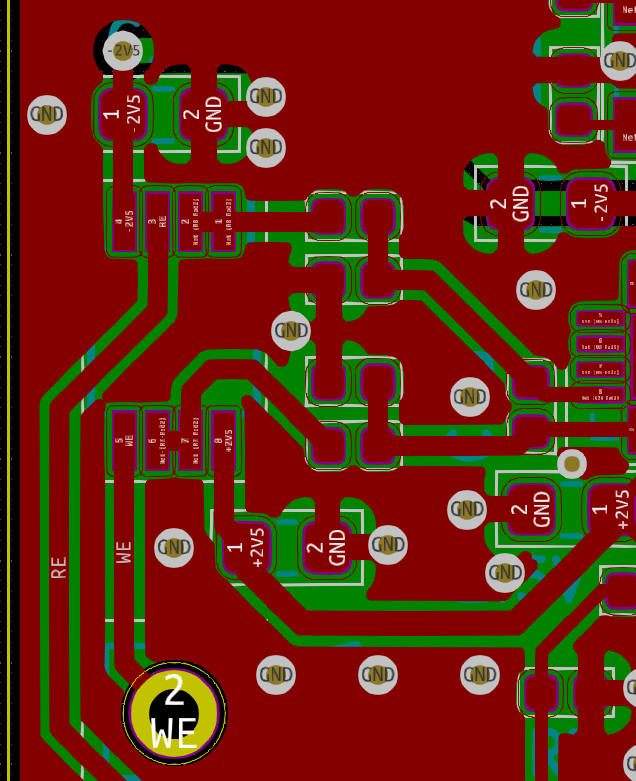

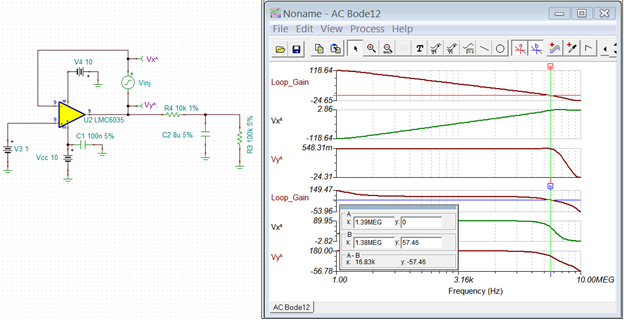

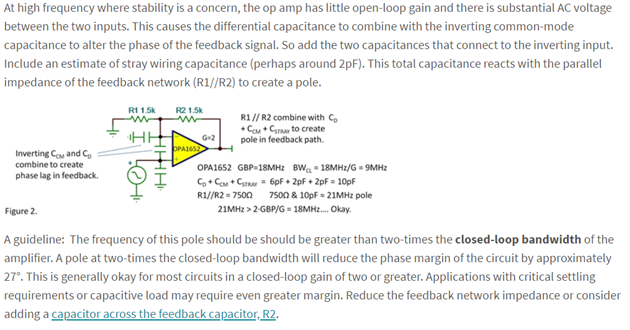

The circuit setup is as following. Is there any such amplifier in a small form factor suitable for my purposes?

Best regards,

Emil