Other Parts Discussed in Thread: OPA2333

Hi Team,

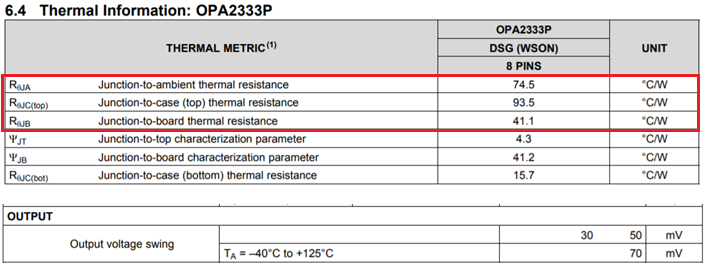

My customer design in OPA2333P in his system, due to PCB is quite small he would like to remove thermal pad then route traces under OPA2333P. Please comment is it doable? Or, is it ok to shrink thermal pad size?

OPAmp drives very small output current to next stage, and it is a portable product supplied by battery.

Thanks a lot.

Vincent Chen