Hi,

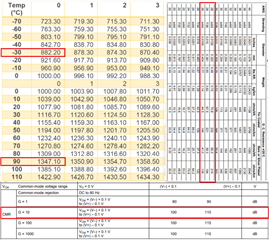

my customer wants to build a solution for radiometric measurement with a PT1000.

Requirements:

- 4.5 - 8m wire between PT1000 and pcb

- 2-Wire measurement is mandatory

- external Ref

- ADC should be the ADS1119

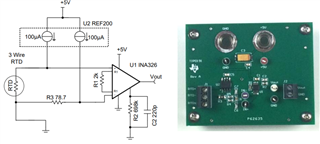

He read the Document SBAA201- RTD Ratiometric Measurements and Filtering Using the ADS1148 and ADS1248 Family of Devices. To build this he needs an external current source for ADS1119.

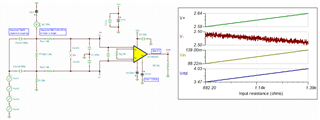

- Q1: Are the recommended steps for common-mode and differential filtering enough to reduce emitted interference

- Q2: Are there special circuits for the current source which have a good immunity against interference. The customer read about the current sources in SBVA001 and SNOA481b (3.1.1.1 Current Source)

Can you please also recommend parts.

Thanks

Jan