Hello Raymond,

Thank you very much for your supports to my previous questions.

I opened this thread because I wanted to ask you again a few additional questions about AN-2029.

Could you please give me your reply for the following questions?

Q1. J-STD-033 has been updated and the latest version is 033D.

In the 033D, the foolowing sentences are added.

5.3.2 Shelf Life The minimum calculated shelf life is 12 months from bag seal date or indicated on barcode. If the actual shelf

life has exceeded 12 months from the bag seal date and the humidity indicator card (HIC) (see 5.5.1) indicates that baking is not

required; then it is safe to reflow the devices per the original MSL rating. However, unanticipated factors other than moisture/

reflow sensitivity could affect the total shelf life of the devices.

AN-2029 doesn't described about this because it is generated base on 033.

But I think the sentences in the 033D is correct for TI because AN-2029 should be excerpt from the 033 standard.

Is my understanding correct?

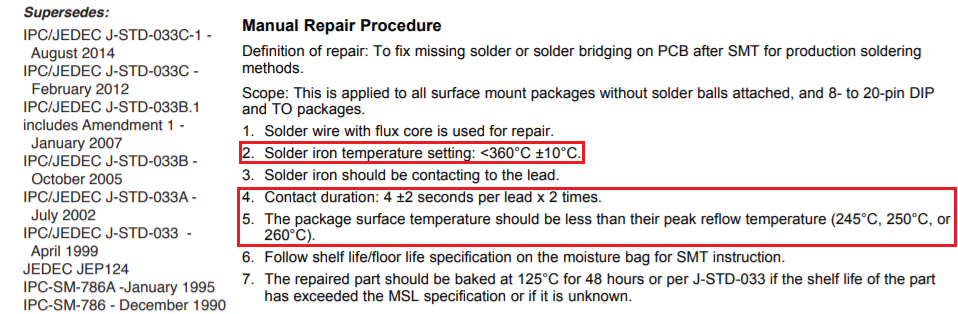

Q2. About "9.Manual Repair Procedure" on page 10 of AN-2029,

Are "2. Solder iron temperature setting: <360°C ±10°C." and 4. Contact duration: 4 ±2 seconds per lead x 2 times".correct

as long as "5. The package surface temperature should be less than their peak reflow temperature (245°C, 250°C, or 260°C)"?

Thank you again and best regards,

Kazuya.

.