How many cores are LMK04816 internal VCO having?

Can I access to the range info for each core?

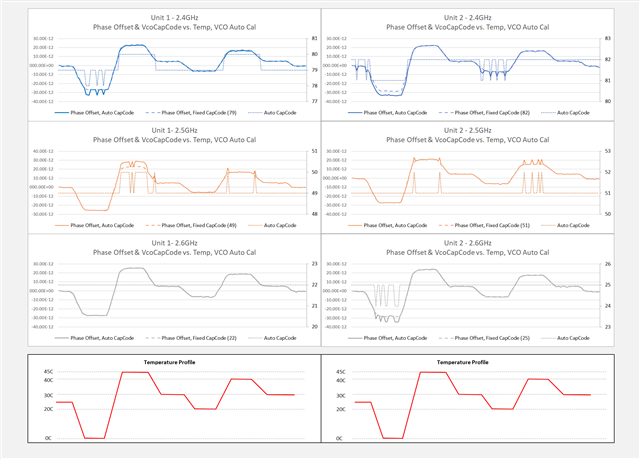

I would like to avoid locking to boundary of 2 VCO cores and causing inconsistent result after each VCO calibration because of choosing between 2 different cores.