Other Parts Discussed in Thread: CDCI6214, , LMK05318B

Hi,

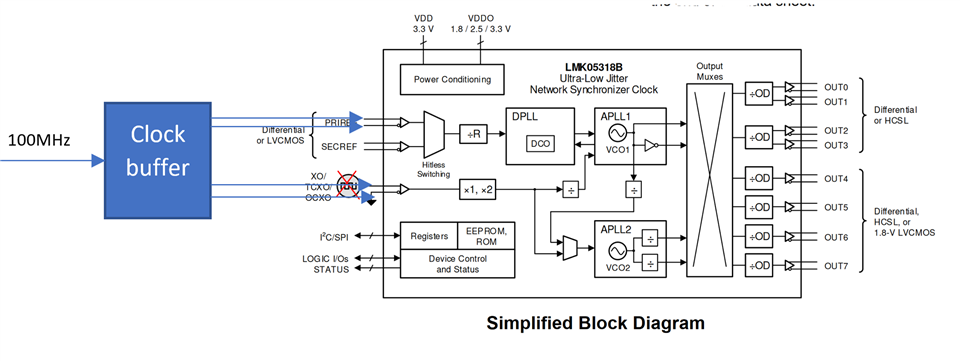

I am going to use a LDO to support clean power to the clock chips on my board, so I need to evaluate the current of LMK03318. There are three types of current consumption spec in datasheet page9. I should add the “core current consumption, per block” and “Current consumption, per supply pin” together to get total supply current, am I right? The “Output current consumption, per block” spec is include in the “Current consumption, per supply pin”, right? I am going to generate 7 channel LVPECL clocks and 1 channel LVCOM-1.8V clock.

Then I get very large current value close to 1A. why the current consumption is so large? I also need to use CDCI6214 in my design, that power spec in the datasheet is only 150mW. For 1.8V power supply, the current is only 80mA that is much more lower than LMK03318. What mistake do I have.

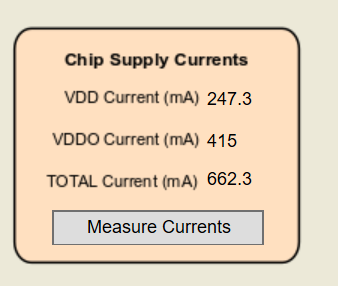

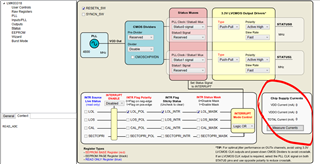

In TICS Pro software, there is one spec call “Chip Supply Current” in “Status” table. May I use this one to get correct current base on the design? Why they are always 0mA? How to make it work?

Regards,

Shu