Other Parts Discussed in Thread: LMX2694-EP, LMX2582

Tool/software:

Hello, Dear TI Support Team

I have purchased the LMX2694-EP evaluation board and am evaluating it, but I have some questions, so I would like to post them here.

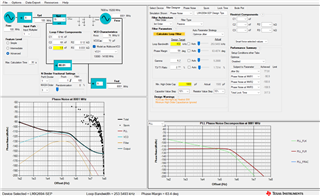

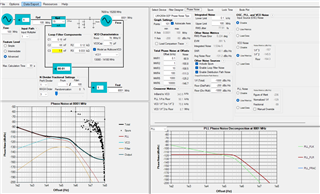

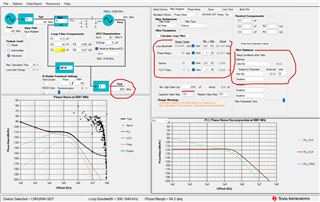

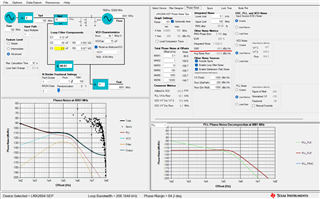

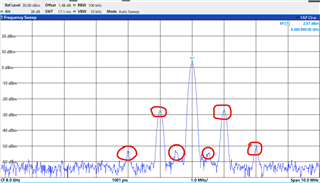

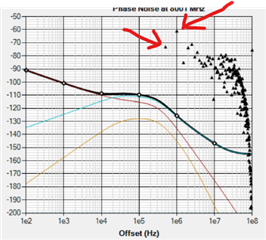

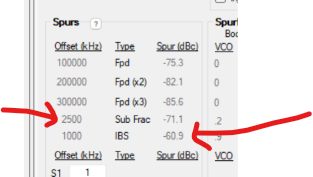

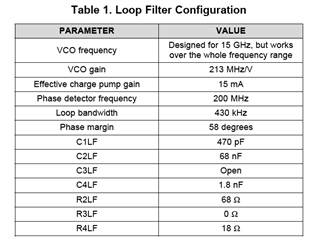

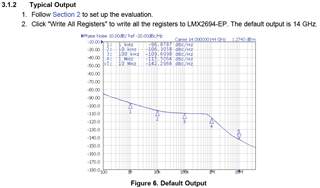

(1) Regarding the results listed in Figure 6 of the evaluation board PDF (snau245.pdf).

I understand that the results in Figure 6 are obtained according to what is listed in Table 1. I also understand that the LoopFilter constants on the factory evaluation board are also the values listed in Table 1.

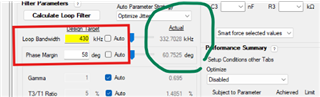

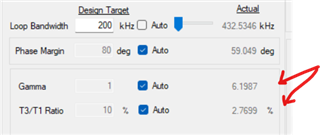

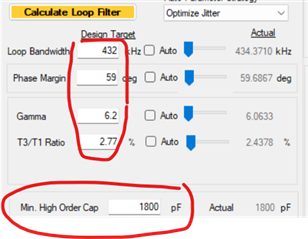

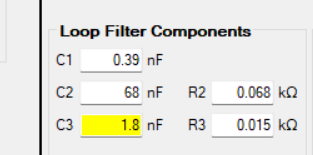

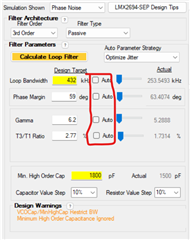

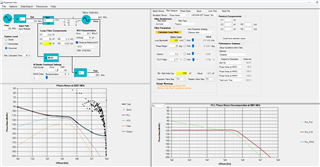

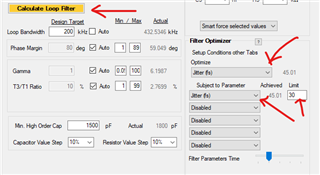

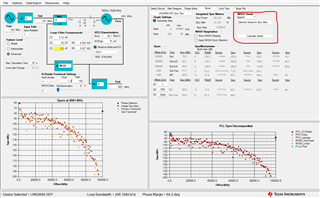

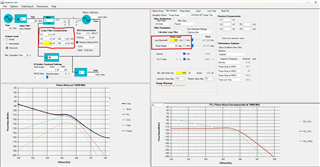

However, when I perform the design under the same conditions with your Sim software PLLatinum Sim, the LoopFilter constants show different values.

I would like to know the cause of this difference and the correct sim method (loop filter design method) to match the results of the evaluation board.

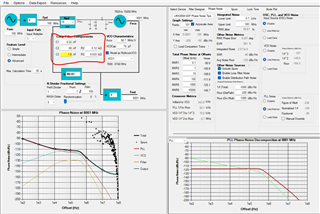

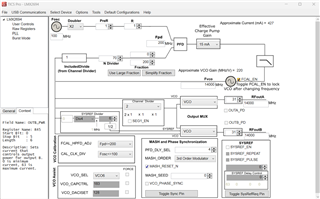

(2) In order to obtain the data described in Fig. 6, should I set up TICS Pro as shown in the following image?

R114 0x720000 R113 0x710000 R112 0x700000 R111 0x6F0000 R110 0x6E0000 R109 0x6D0000 R108 0x6C00F1 R107 0x6B0000 R106 0x6A0007 R105 0x694440 R104 0x680000 R103 0x670000 R102 0x660000 R101 0x650000 R100 0x640000 R99 0x630000 R98 0x620000 R97 0x610000 R96 0x600000 R95 0x5F0000 R94 0x5E0000 R93 0x5D0000 R92 0x5C0000 R91 0x5B0000 R90 0x5A0000 R89 0x590000 R88 0x580000 R87 0x570000 R86 0x560000 R85 0x550000 R84 0x540000 R83 0x530000 R82 0x520000 R81 0x510000 R80 0x500000 R79 0x4F0000 R78 0x4E0064 R77 0x4D0000 R76 0x4C000C R75 0x4B0800 R74 0x4A0000 R73 0x49003F R72 0x480001 R71 0x470080 R70 0x46C350 R69 0x450000 R68 0x4403E8 R67 0x430000 R66 0x4201F4 R65 0x410000 R64 0x401388 R63 0x3F0000 R62 0x3E0322 R61 0x3D00A8 R60 0x3C09C4 R59 0x3B0001 R58 0x3A8001 R57 0x390020 R56 0x380000 R55 0x370000 R54 0x360000 R53 0x350000 R52 0x340420 R51 0x330080 R50 0x320000 R49 0x314180 R48 0x300300 R47 0x2F0300 R46 0x2E07FD R45 0x2DC8DF R44 0x2C1F23 R43 0x2B0000 R42 0x2A0000 R41 0x290000 R40 0x280000 R39 0x2700C8 R38 0x260000 R37 0x258404 R36 0x240046 R35 0x230004 R34 0x220000 R33 0x211E21 R32 0x200393 R31 0x1F03EC R30 0x1E318C R29 0x1D318C R28 0x1C0488 R27 0x1B0002 R26 0x1A0DB0 R25 0x190624 R24 0x18071A R23 0x17007C R22 0x160001 R21 0x150401 R20 0x14F048 R19 0x1327B7 R18 0x120064 R17 0x11012C R16 0x100080 R15 0x0F064F R14 0x0E1E70 R13 0x0D4000 R12 0x0C5001 R11 0x0B0018 R10 0x0A10D8 R9 0x091604 R8 0x082000 R7 0x0700B2 R6 0x067802 R5 0x0503E8 R4 0x040E43 R3 0x030642 R2 0x020500 R1 0x010809 R0 0x00211C

Please answer the above two questions.