Other Parts Discussed in Thread: LMX2531

Tool/software:

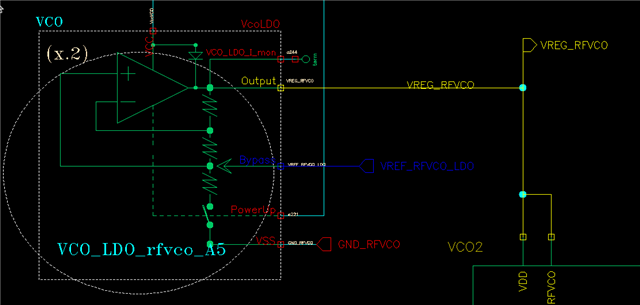

The datasheet shows 10uF and 0.1uF capacitors used for on-die LDO "bypassing". No mention is made of the dielectric material for these capacitors. If these capacitors are noise bypasses on an internal reference for the internal LDO's, then X5R and X7R with their piezoelectric effect will generate noise from vibration. To avoid that vibration susceptibility film capacitors would be preferred for the 10uF (the 0.1uF can be COG). If they locally bypass the supply to the internal regulator, then the external supply regulator can cope with that by servoing out vibration noise these capacitors would suffer. Can it be clarified if these bypasses are for low noise filtering for the internal regulator reference, or for internal regulator input supply?

Thanks,

Farron Dacus