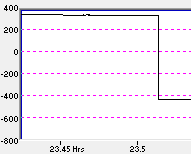

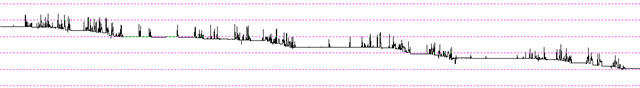

We have been using ADS1232 in high resolution load cell applications since ~2010. Recently we've had an increasing number of sudden, inexplicable level shifts that ruin long-term recordings. To show you what we're dealing with, here is a good recording (duration about 80 hours):

The occasional disruptions are expected, and caused by interactions with the load cell that we need to quantify. As you can see, between interactions the load cell signal is nice & constant. The slow decline over the 80 hours of the recording is exactly what we expect.

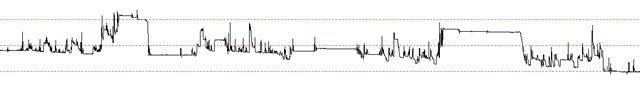

Here, in contrast, is a bad recording:

As you can see, the trace shows sudden level shifts, steps up or down, that appear at random & have different amplitudes. This makes it impossible to quantify the interactions, because they are riding on a hugely variable signal.

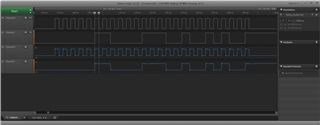

At first we thought that we had clock issues, because the changes are step-like & could be caused by mis-shifting data. However the clock & data lines are short (a few cm) and appear to be clean (scoping with a digital 'scope & a Saleae logic analyzer). We get this issue with 2 different microcontrollers (a PIC & an ESP32). And of course we initialize the ADS1232 correctly, including an initial offset calibration.

This is driving us insane (or at least, even less sane than we were to start with). Do you have an suggestions that might help us?

Thanks in advance!