Other Parts Discussed in Thread: ADS1298

Hi,

The ADS1298R datasheet tells that I can choose DC/AC leadoff detection.

And the DC detection has a) Pull-Up/Pull-Down Resistors b) Current Source methods.

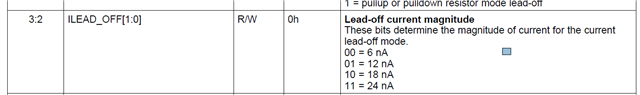

And the Current Source has ILEAD_OFF registers to set the current magnitude.

My Question is, what should I concern when I choose the LeadOff method?

I think the input impedance is as larger as possible, isn't it? So the current source is the best choise, isn't it? If it is, what value should I set to ILEAD_OFF?

Thank you.

Frank