Other Parts Discussed in Thread: OPA377-Q1, OPA192-Q1, TLV197-Q1, OPA376-Q1, OPA320-Q1, OPA197-Q1, OPA340, OPA340-EP

Hello,

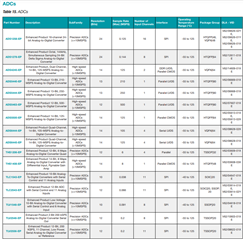

I am trying to determine how closely the qualification test data matches with AEC-Q100 level screening for the ADS7887SDBVT and the V62/08618-01XE parts.

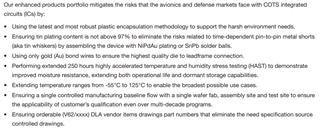

I could not find the screening/qualification test flow for the ADS7887SDBVT analog to digital converter and the V62/08618-01XE Op-Amp, Could you please point me in the right direction for where these documents are located. I am looking for the TI lot screening tests that are done on these two part numbers (visual inspection, temperature cycling, burn-in, etc.)

I am also looking for information related to any part level qualification test data that the parts were subjected to such as life testing, or any information related to any testing that is done on these parts at either a lot level, or at a qualification level.

Thank you,

-Neil Gagne