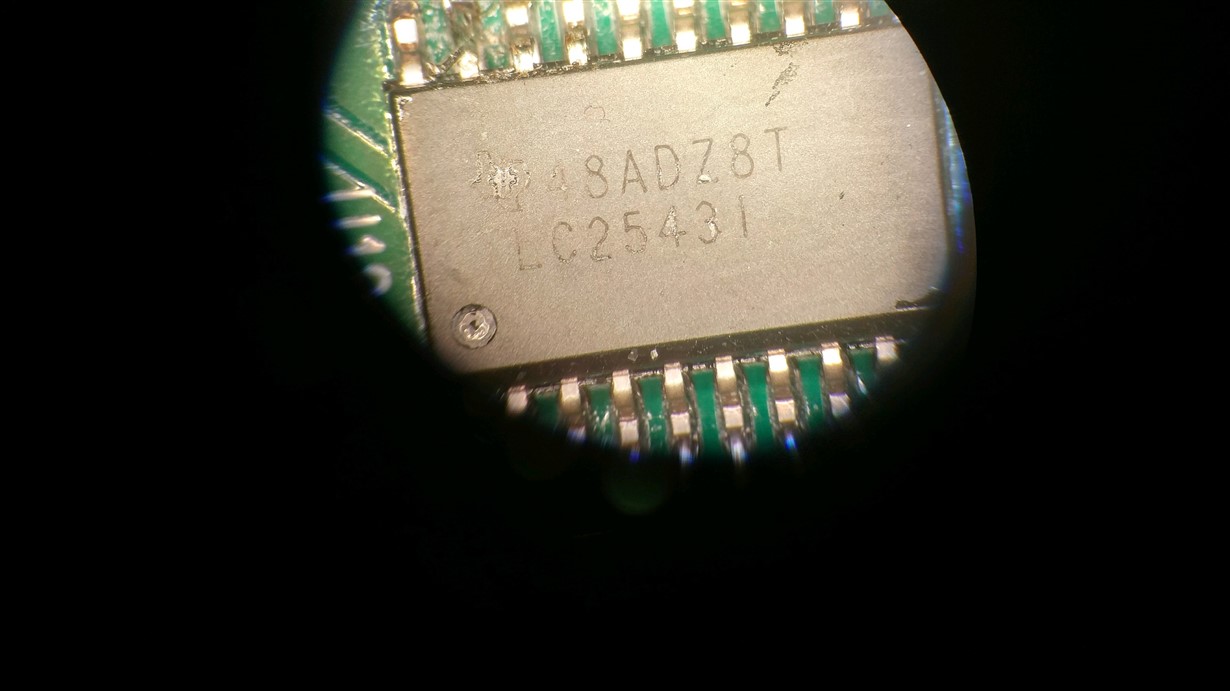

Other Parts Discussed in Thread: TLV2556

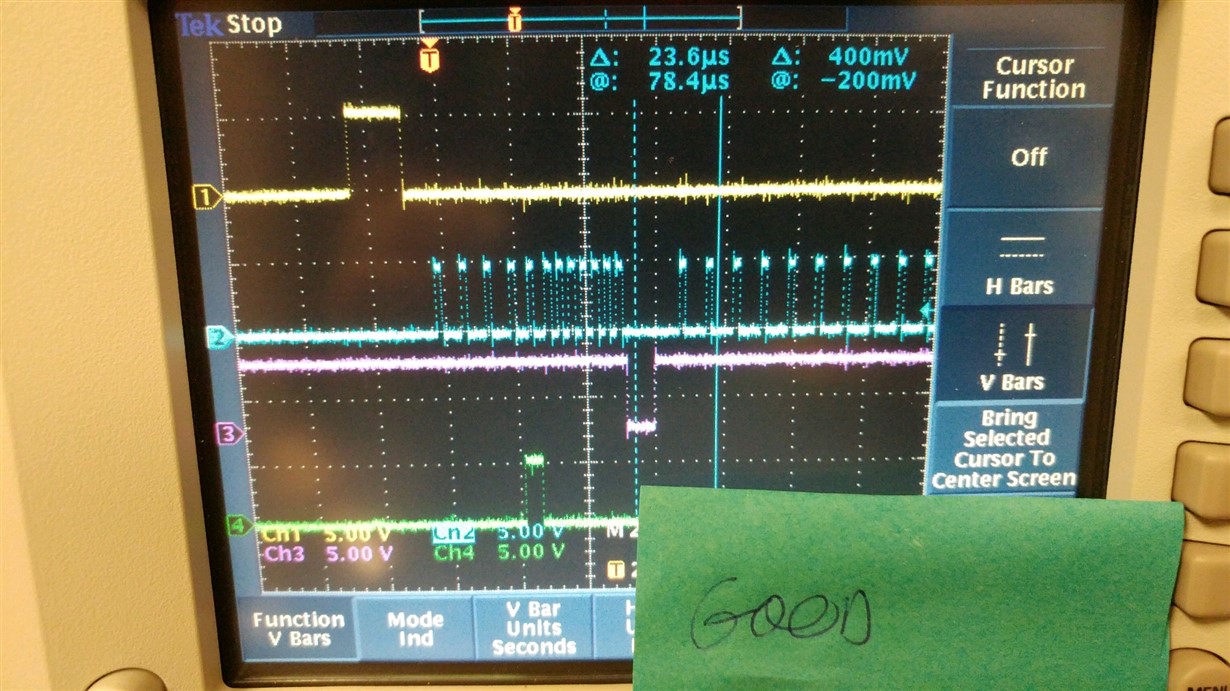

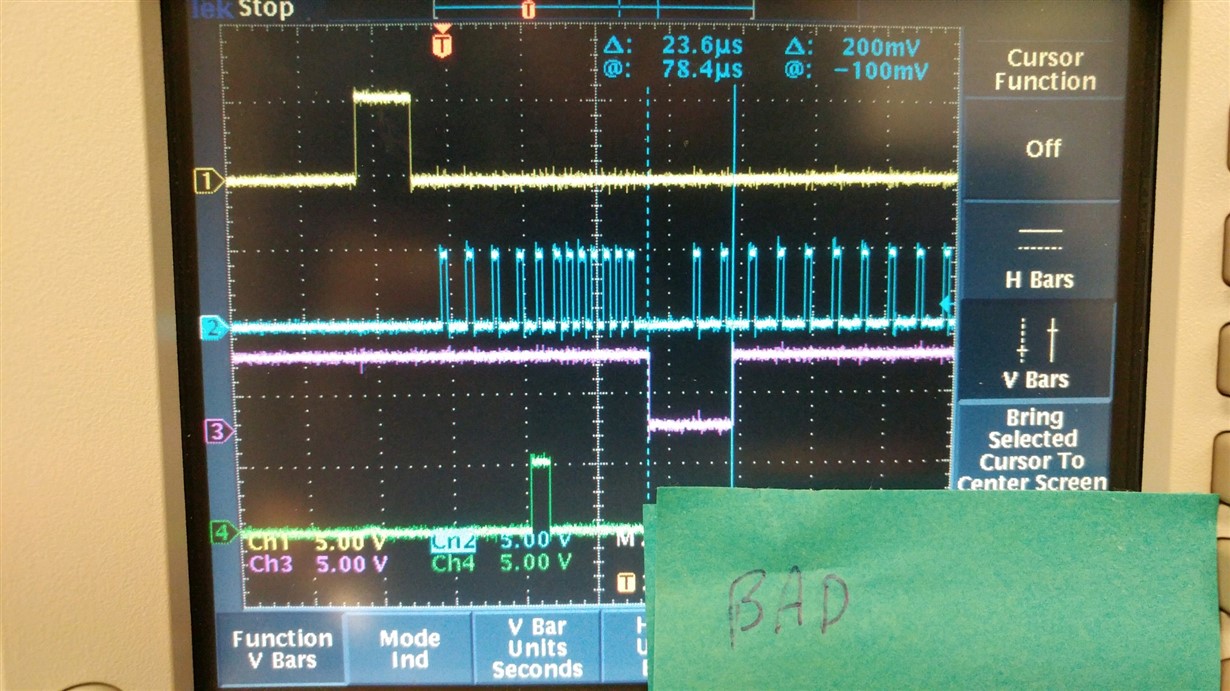

We are having to replace the TLC2543 parts on a regular basis to get our product to work. I have taken a look at the part and notice that upon initialization the part will either operate correctly or sometimes (tends to be worse at colder temperatures on affected parts) the part looks to operate normally except the EOC signal stays low for 23us which is far beyond the specified maximum of 10 us. Once the EOC goes low for 23 us , then it stays at 23 us every single time that EOC goes low. Also , if the EOC is correct, then it is always correct. This is causing our system to hang up. I have attached a scope traces of a good EOC signal and a bad one. Why is the EOC signal going past the 10 us maximum? Any suggestions to keep EOC in spec under all conditions?

Yellow = CS

Blue = Data

Pink = EOC

Green = address