Other Parts Discussed in Thread: , ADS1235

Hi everyone,

Currently, i'm designing an industrial weith scale with a maximun weight of 15 tons (6 load cells of 3 tons each connected in parallel). The main requeriments are a resolution of 50 kg approx. (easy for 24 bit resolution) and thermal stability.

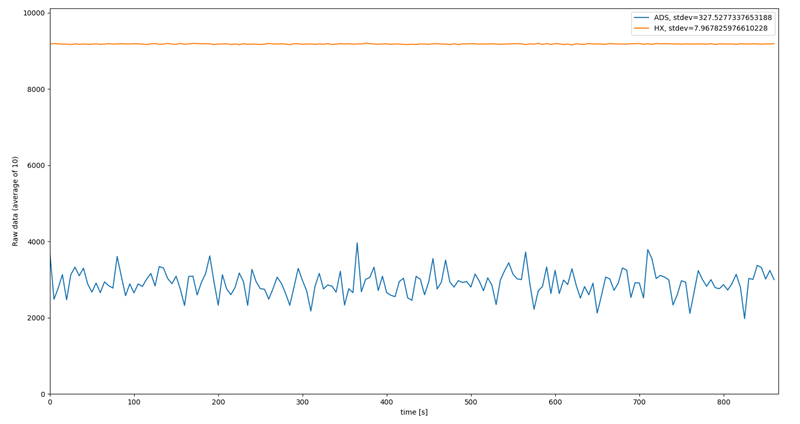

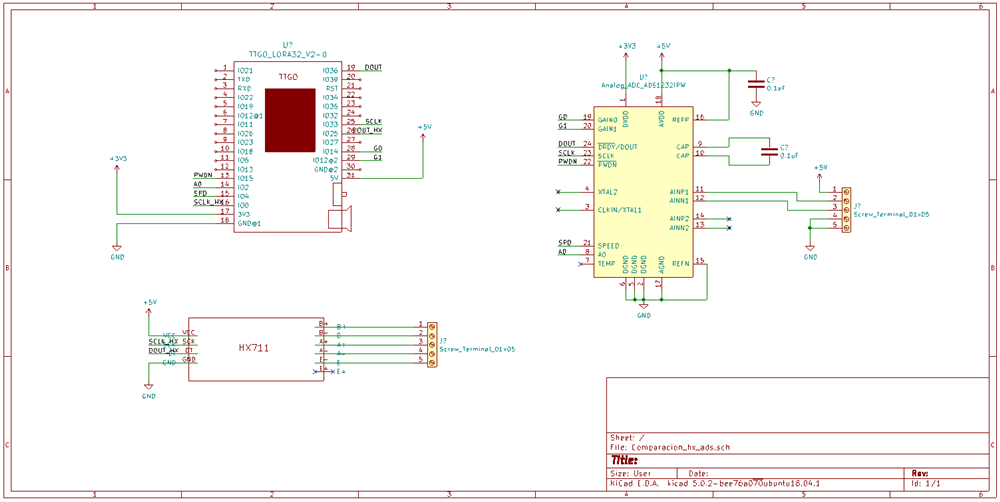

I have been testing the ADS1232, but my prior results are really bad, with a high noise level (compared to the results of the HX711). In my previous configuration i didn't consider filters for the analog signal.

My question is, is the ADS1232 a good choice for this application, considering the thermal stability? Are analog filters critical for the application considering that the HX doesn't use it?

As i can see in the diagrams of the ADS1232REF user's guide, are filters used for digital signals, is it necesary?

Thanks you!