Hi,

Inquiry about CapTIvate-Metal has been received from a customer.

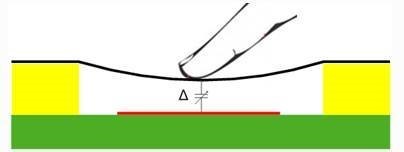

There is a message that the gap should be formed as shown in the figure below.

Do I really need a gap?

Are there any comparison data between general capacitive touch solutions and metal touch solutions? (data such as recognition rate)

Thanks.

Regards,

MJ