Other Parts Discussed in Thread: OPA141,

Dear All,

My last problem was solved with your help. Thanks again.

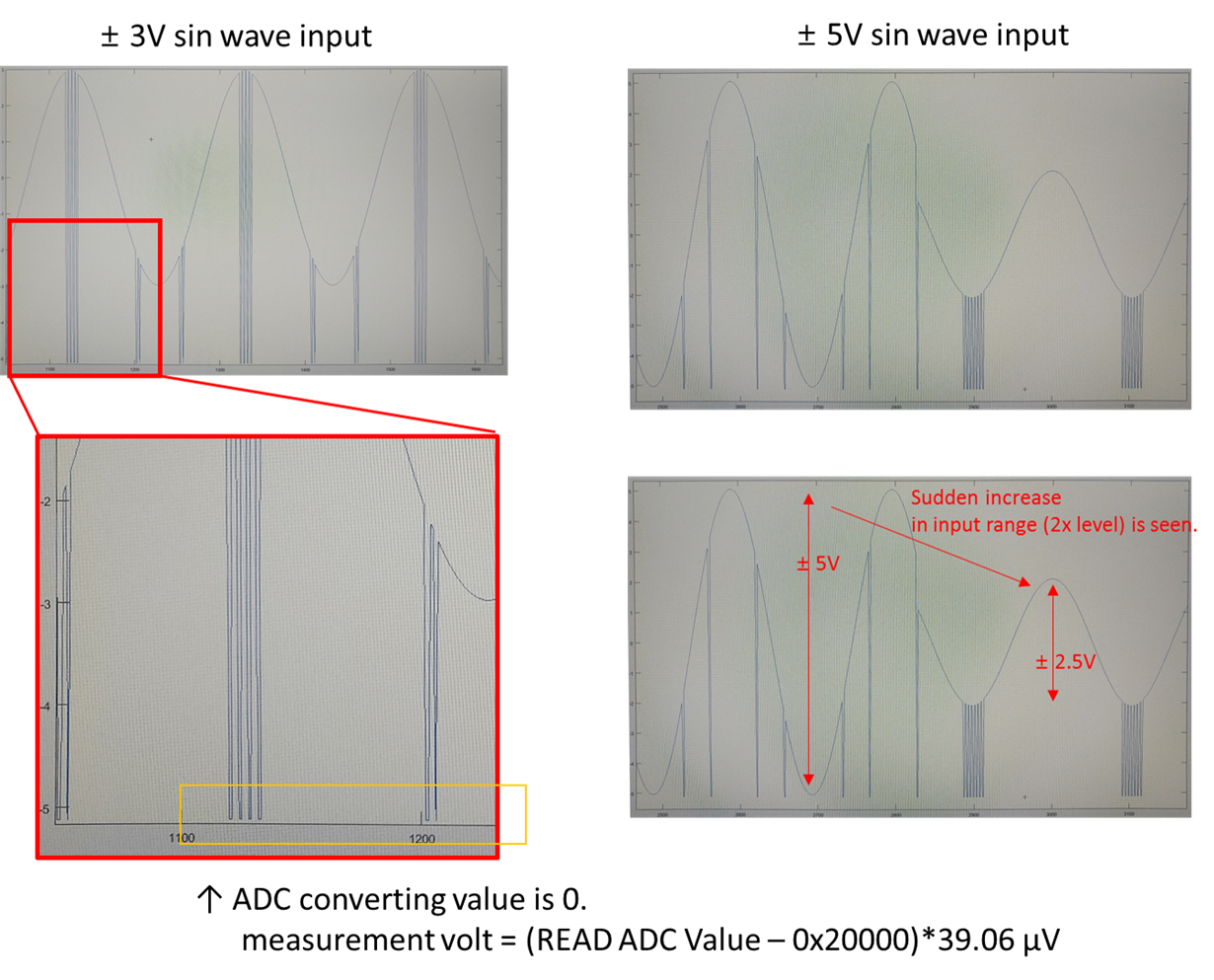

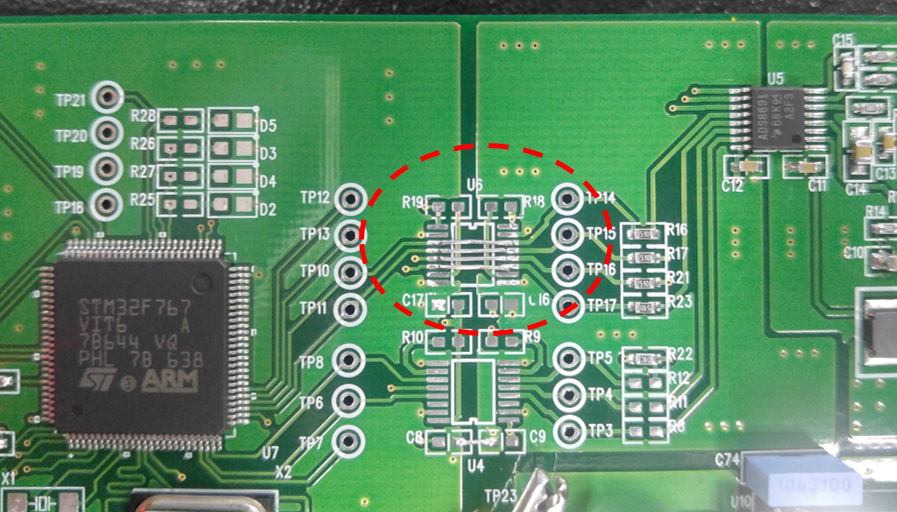

When the ADC input test was performed based on the completed code, it was found that the converted value was abnormal when a sinusoidal voltage signal having a specific voltage (about 1.6 V) or more was input.

However, it does a stable and accurate conversion for input signals below 1.0V.

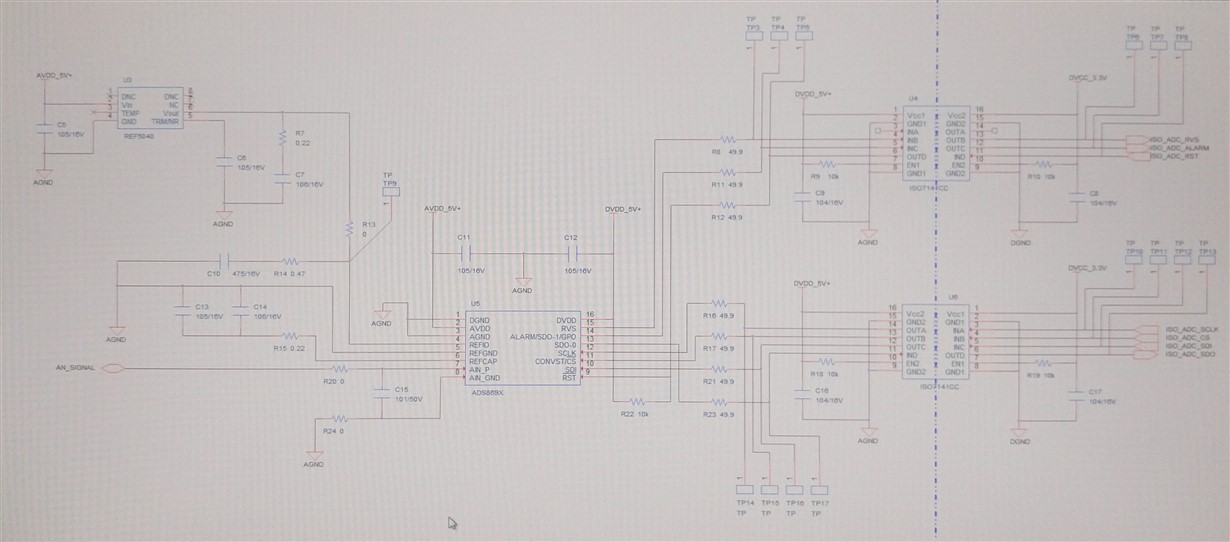

The operating conditions of my ADC are as follows.

Input Range of ADC: ± 5.12V

Signal source: function generator (output impedance: 5 ohms)

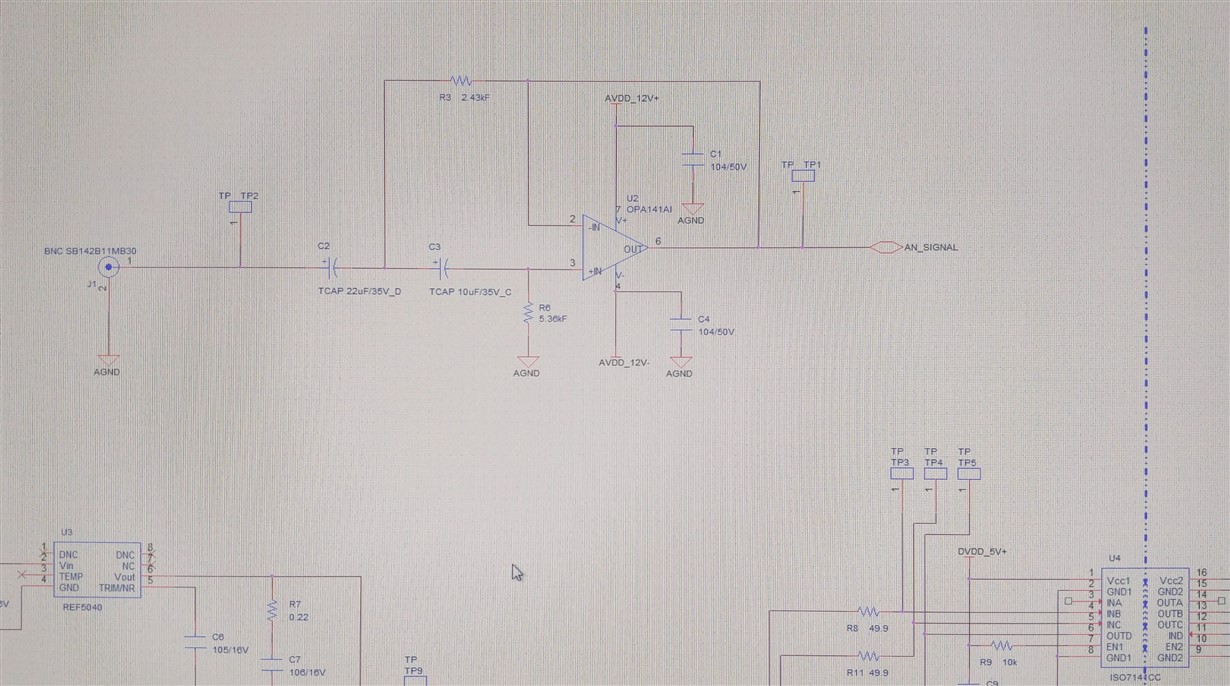

Signal source and ADC side element: 5Hz 2nd-order HPF with OPA141

Sampling: 4096 at a rate of 16,384 per second, collected for 250 msec.

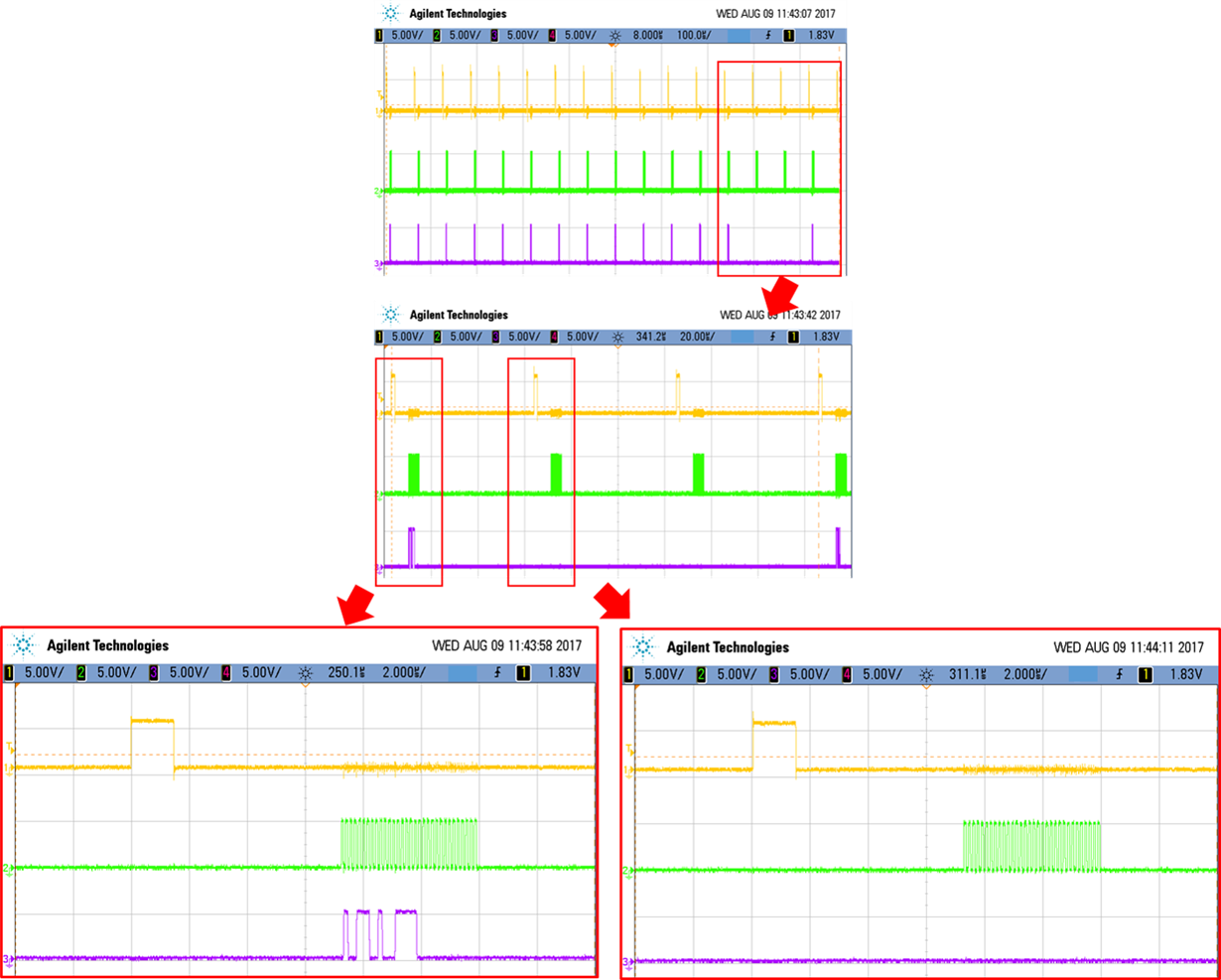

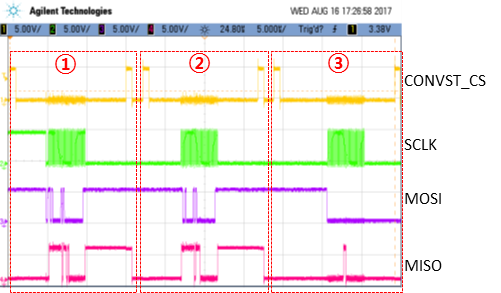

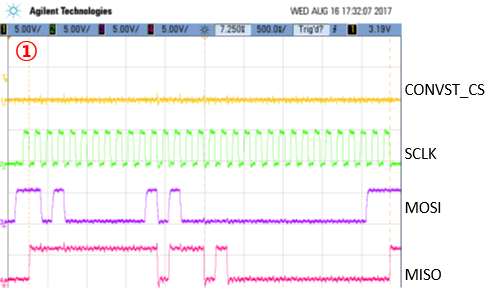

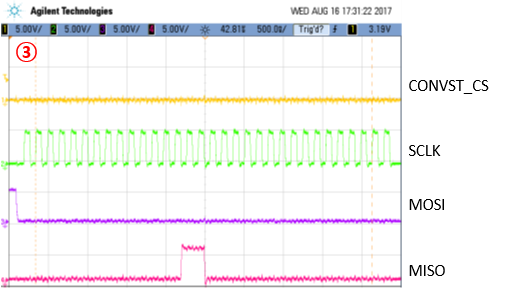

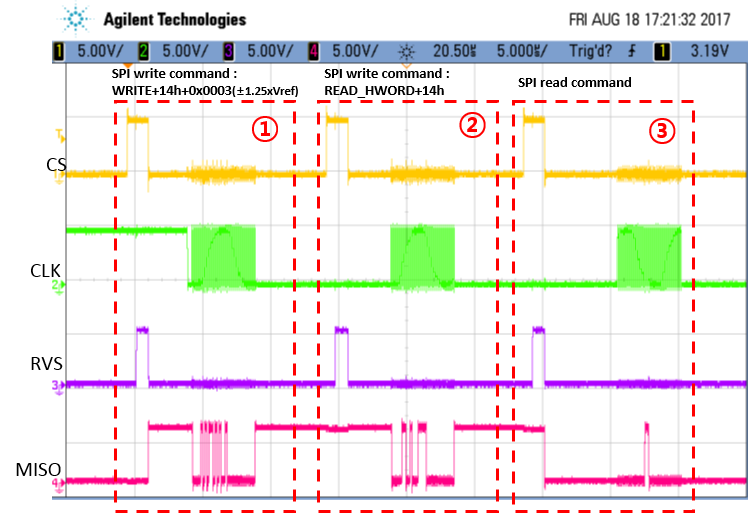

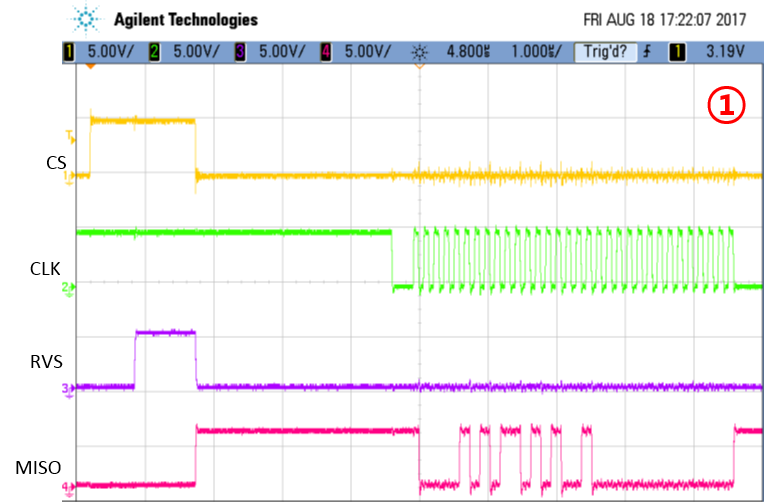

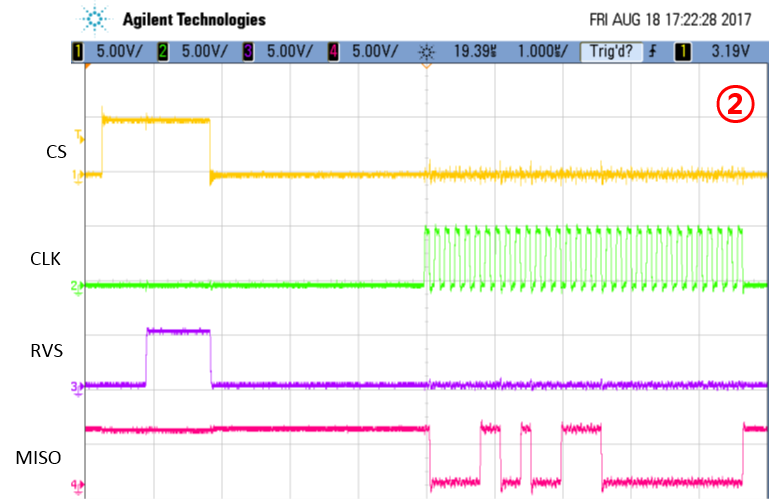

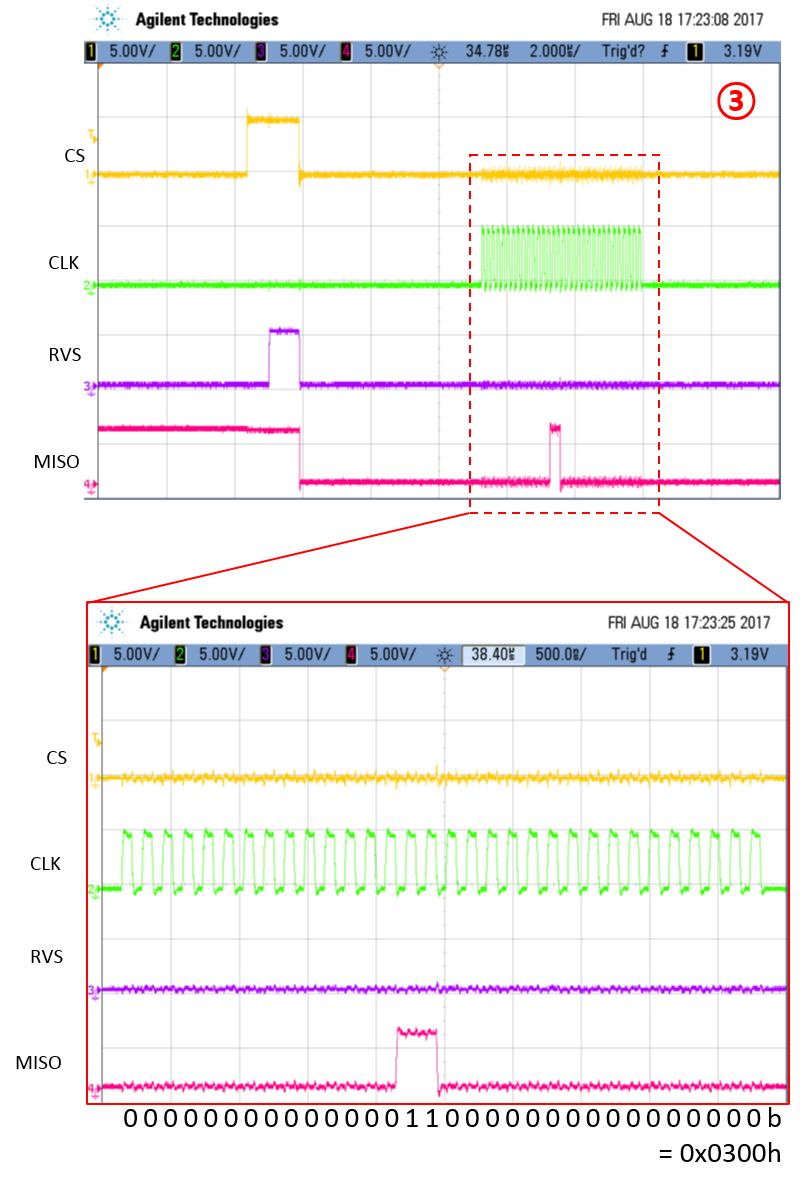

The converted value does not match the set input range and periodically outputs a value of 0.

Analysis of the oscilloscope waveform shows that zero MISO signal is output from the ADC.

In these symptoms, are there any cases that can be classified as probable problems or potential failures?