Part Number: ADS124S08

Other Parts Discussed in Thread: ADS1235-Q1, LM53600-Q1

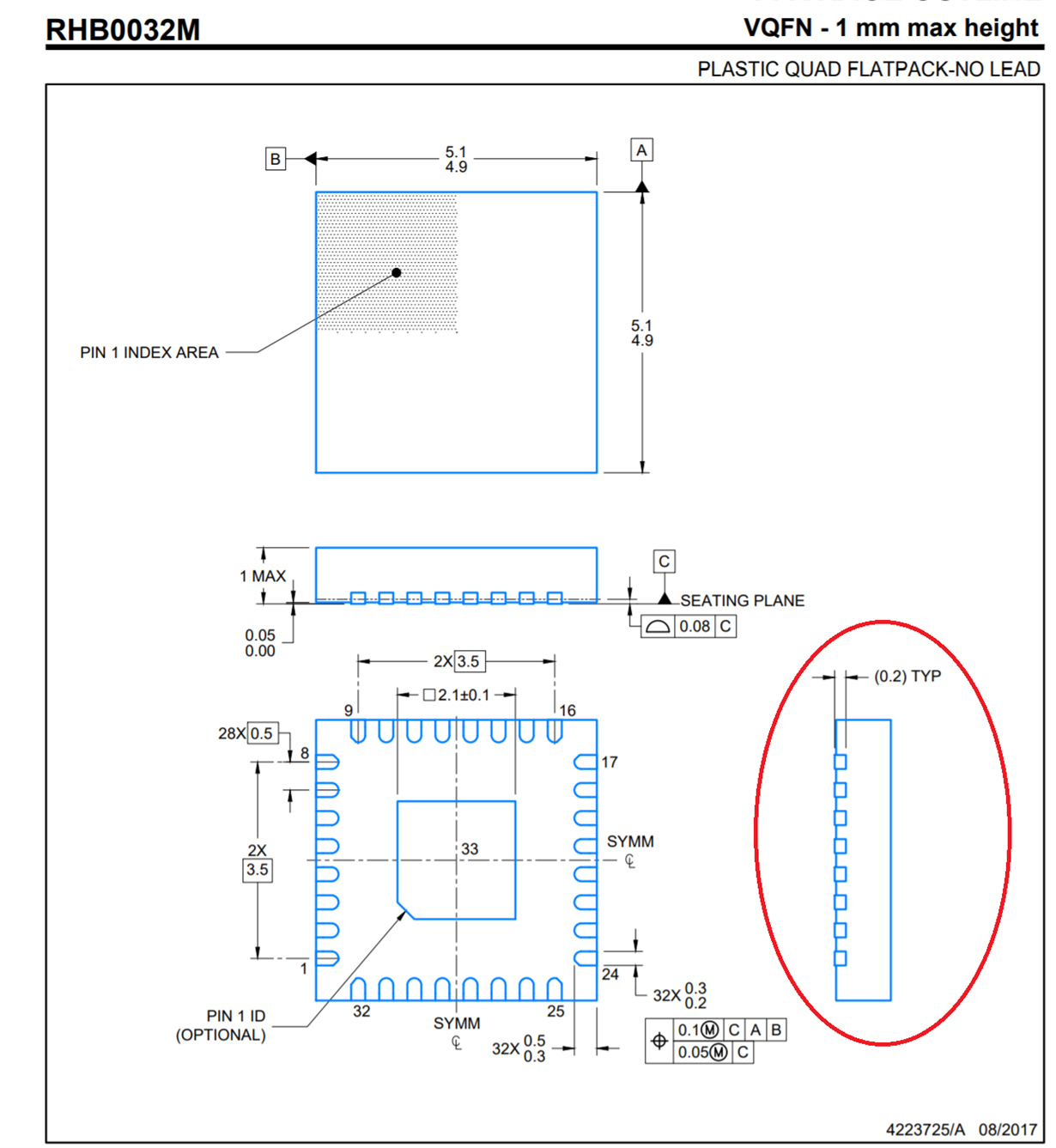

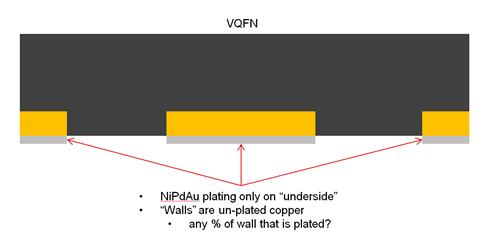

This is a not often seen request, but I have a customer asking me what the thickness of the thermal pad is for the VQFN version of the ADS124S08 (ADS124S08IRHBR)

Regards,

Darren