LightCrafter-aficionados,

Young Optics has done a great job in creating a compact light engine for LightCrafter. To explain the light engine, I have disassembled one of our units. I removed the cover on the top and bottom of the light engine. I also removed the Red LED heat sink and the Green and Blue LED heat sink. Note that any disassembly of the light engine voids the warranty on the LightCrafter system.

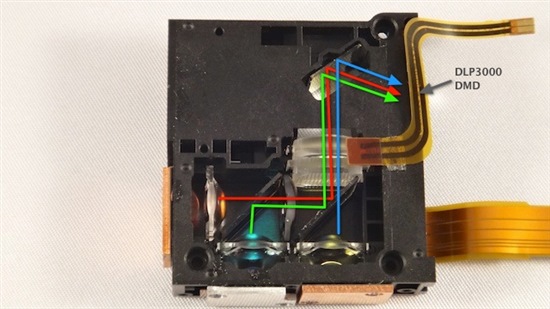

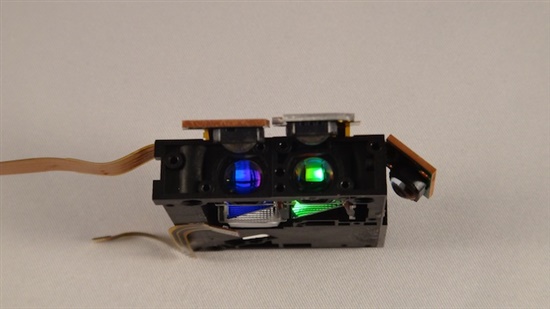

The following photo shows the top side of the light engine. The flex cables supply power to the LEDs. The DLP3000 DMD lies vertically on the top left hand side in front of the projection and focus lenses. The LEDs lie between the heat sink and light engine.

Each LED has an optical collimator to collect the wide beam of light from the LED and produce a narrower beam. This narrow beam of light passes through a set of dichroic mirrors that reflect a specific color of light while letting other colors of light pass through it. The dichroic mirrors recombine the different colors of light into one co-linear beam. The recombined light passes through a fly-eye and condenser lens that provides uniform light intensity. This uniform light intensity beam is directed towards the DLP3000 DMD.

Here are the paths of the red, green, and blue light:

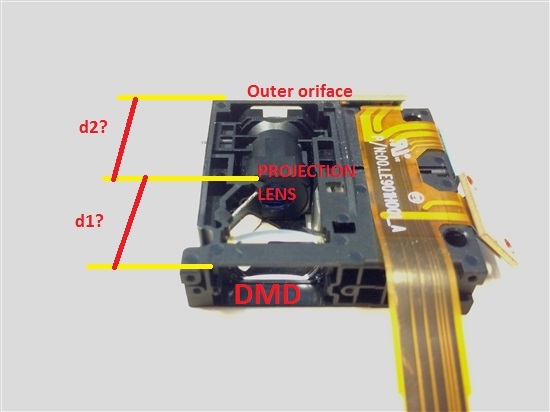

When the DLP3000 pixels are in the on-position, light is reflected through the projection lens. When the DLP3000 pixels are in the off-position light is directed towards a light absorber barrier.

![]()

Here is a view of the dichroic mirrors in operation, see how only green and blue light are reflected from ambient light.

A final photo of the light engine with the LEDs removed. Copper sheets are used to dissipated the heat of the LEDs into the heat sinks. The top and smaller flex cable has a photo sensor next to the condenser and fly-eye lenses. This photo sensor is connected to DLPC300. The Green LED has a thermistor to measure the temperature. This thermistor is connected to a MSP430 ADC channel.