Hello,

We have soldering issue with the TUSB7340 USB3.0 xHCI controller WQFN-100. This QFN component has dual row on all sides with a large thermal pad in the middle. We have soldering/ wetting issue on the inner row resulting in open. This issue is seen on X-ray inspection and happens on random pads of the component. The yield loss in production is close to 100%. Interestingly, X-ray inspection of BGAs on the same PCB is good.

The following process improvements were made but did not improve the yield.

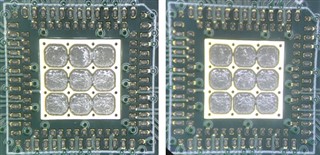

1. Improved stencil design, adequate tooling support and printer settings which has resulted in good solder paste deposit, please see attached .

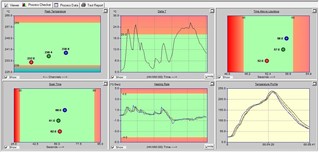

2. Reflow profile optimised according the recommendations of the solder paste (Indium 8.9 PB free T4 SAC305). This includes soaking for above 60 seconds, reflow time close to 60 secs and peak temperature of 238°C.

Please see below for further investigation,

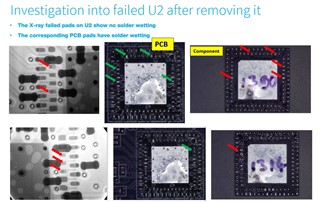

1. After removal of the failed component from the PCB, it is seen that there is solder wetting on the PCB pads but not on the component pads, please see attached.

.

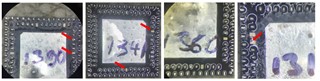

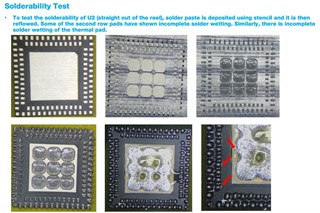

2. Solderability test of the component pads was done by screen printing solder paste directly onto the component pads & reflowed. It was ensured the pads were not contaminated by handling etc. There is evidence of incomplete wetting on some of the pads on the inner row and the large thermal pad.

3. Trials in which the component and PCB pads were cleaned using Iso-propanol alcohol & acetone to remove any contamination did not yield a good result. Visual inspection of the component out of the reel did not show any contamination or oxidation.

4. Trials in which flux was added to the component & PCB pads did not yield a good result.

5. Pre-tinning & wicking the component pads did not yield a good result.

Any technical assistance would be appreciated to resolve this issue. Please advise if further information is required.

Thanks.