Other Parts Discussed in Thread: THVD8010

The contents below are about performing OOK operation at -40℃, and we request technical support for the operation.

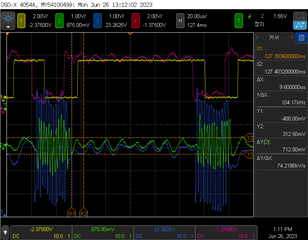

The two waveforms below are measured from one communication packet.

|

|

|

1. Abnormal waveform |

2. Normal waveform |

Waveform description

Yellow: Master Rx, Green: Master A-B, Red: Slave Tx, Blue: Slave A-B

The support request is to error operation and normal operation in the part of the oscillating (58 kHz and 104kHz) after the ON/OFF keying (500 kHz).

- Request technical support for the reason for error operation at 58 kHz.

- Request technical support for the reason for normal operation at 104 kHz.