Other Parts Discussed in Thread: TMDS64EVM, DP83867ERGZ-S-EVM, DP83869HM, DP83869EVM, DP83869

Hi Team,

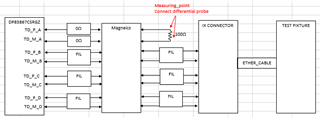

We are using DP83867CS on our development board,

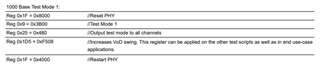

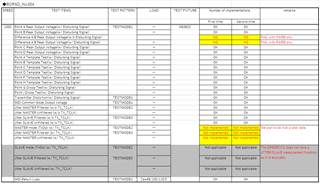

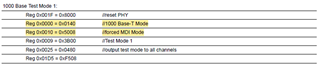

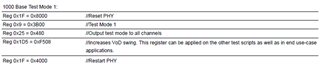

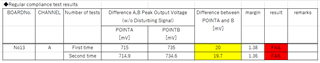

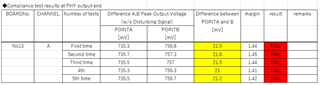

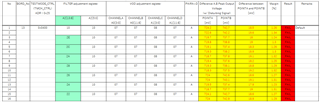

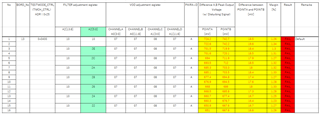

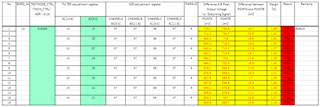

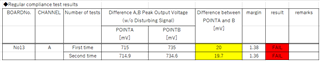

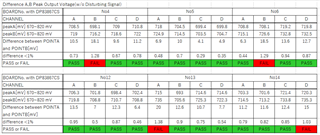

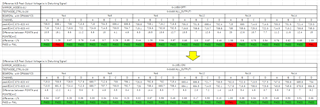

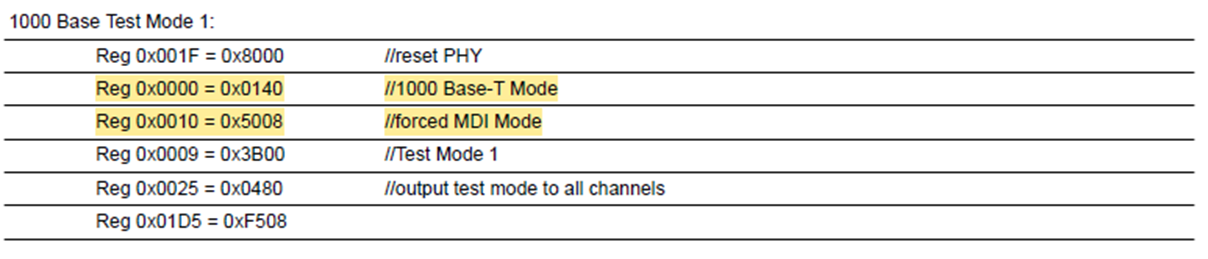

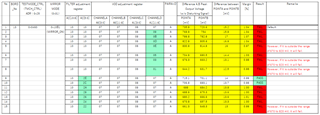

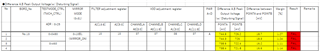

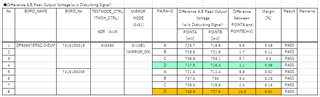

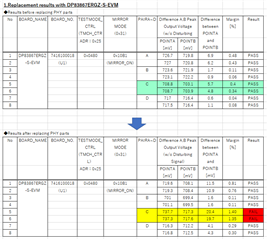

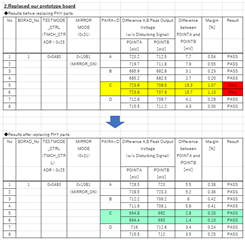

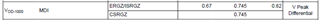

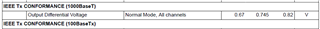

An issue occurred during the 1000Base-T compliance test.

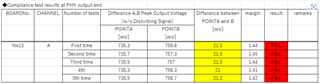

The test fails in the following section:

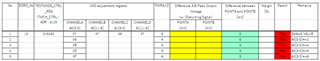

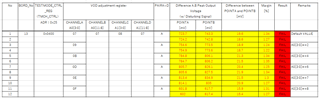

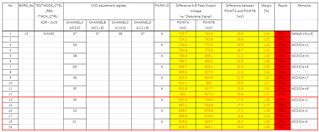

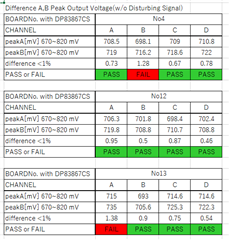

[1000 Base-T, difference A, B peak output voltage (w/o Disturbing Signal)]

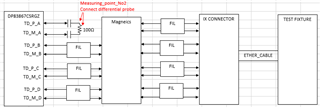

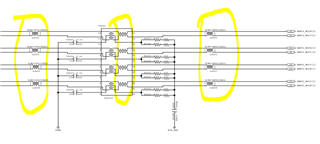

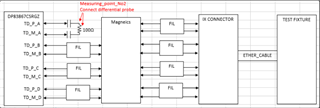

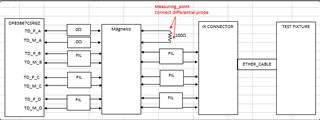

Please take a look at attached file for the details.

We would appreciate any advice regarding the results of the compliance test.

【Question1】

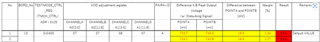

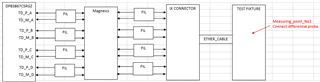

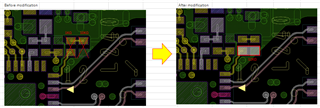

The above No.4_Board and No.12_Board and No.13_Board differ only in PHY parts.

From the above test results, I think there may be variations in port Difference A,B Peak Output Voltage depending on the component.

Could you please tell me how to improve the above?

【Question2】

I checked a thread similar to this issue.

But I couldn't figure out how to improve it.

You can also see a thread about this issue in the E2E community, but it's a private communication and I don't understand the solution.

Could you please share your solution to resolve this issue?

<e2e>:e2e.ti.com/.../dp83867ir-10base-te-100base-tx-1000base-t-compliance-test

Best Regards,