Other Parts Discussed in Thread: USB2ANY

Tool/software:

Hello TI experts:

we are facing some issues when using the UB962 and UB935.the source tickets can be found here.

We are using the TDA4->UB962->UB935->OVX3F for our video pipline.

and currently we found a issue which happens in a small probability event.

some of the I2C wave lost when we are trying to write some register:

and we connect all I2c between the TDA4 and camera

for our system we use TDA4->UB963->UB935->x3fcamrea

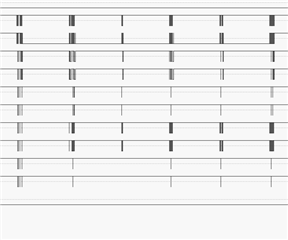

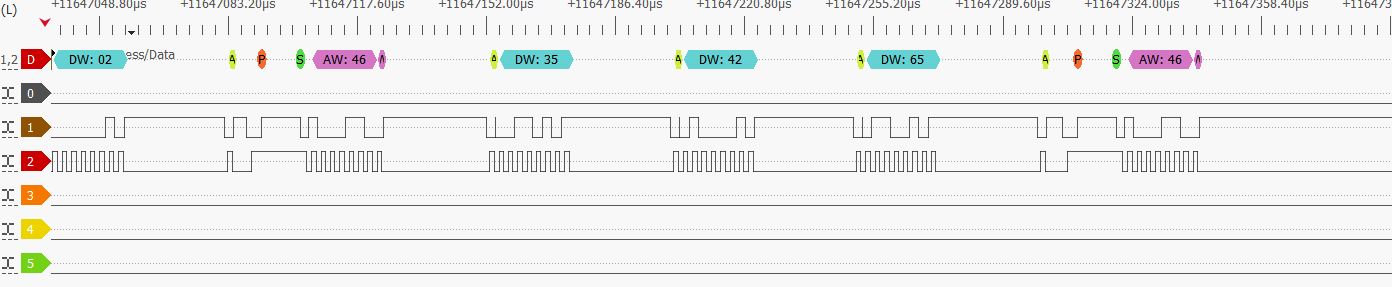

and I measures all I2C in the system which is TDA4 I2c with UB962 and UB935 i2c with x3fcamera as follows

channel 1 2 is for the TDA4 side

channel 3 4,5 6, 7 8, 9 10 for the x3f camera side

and in the timeline 10.75S here is a no ACK issue here

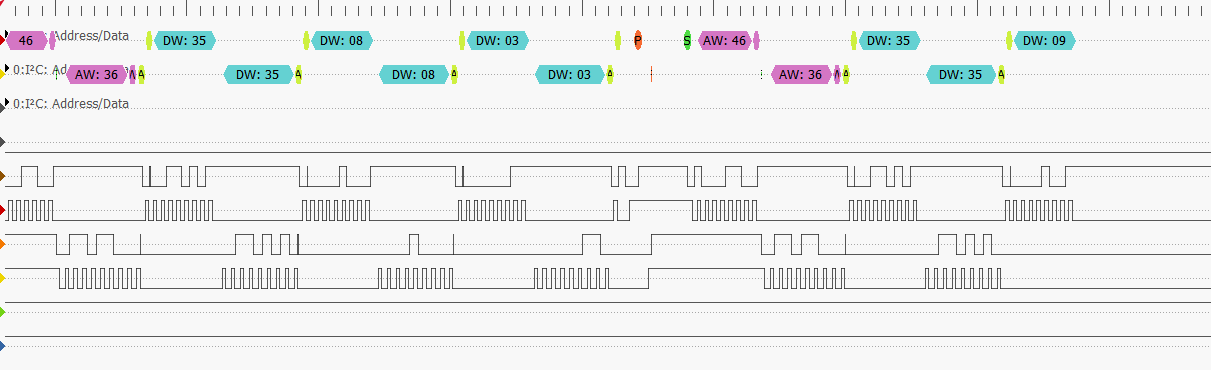

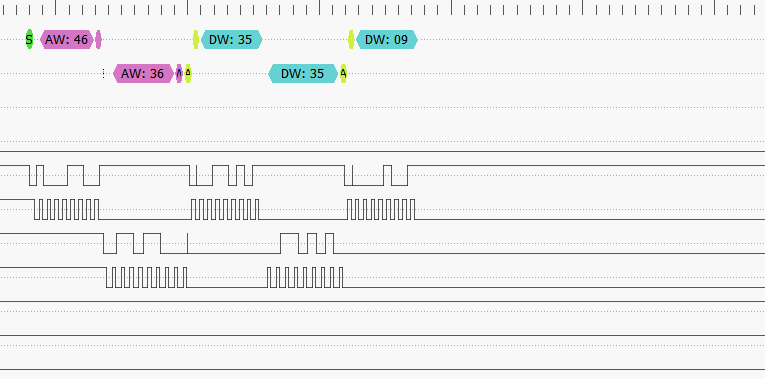

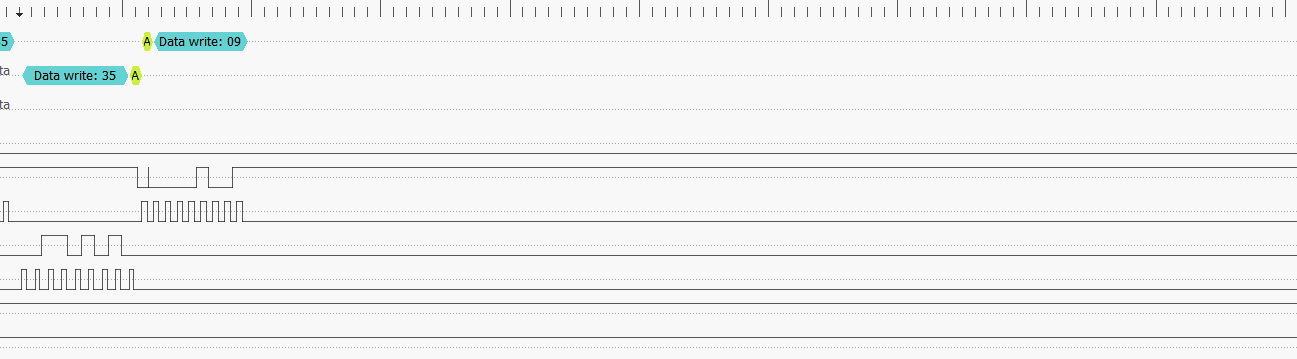

and if I zoom in the waves

it trying to write some register to camera,

but when address 0x36 and the first reg data 0x35 was write to the camera

the next data 0x09 have not send by the UB935

it seems the 0x09 data was lost in the data line.that is very strange here.

could you pls help us why the data lost here.

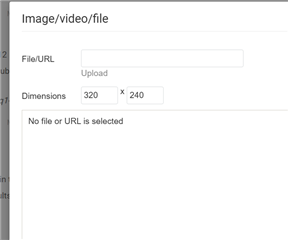

and for the configuration of the UB962 and Ub935 can be found here

e2e.ti.com/.../ds90ub962-q1-ds90ub962-q1-greelysmart-ub962-ub935-register-configuration