Other Parts Discussed in Thread: LSF0102

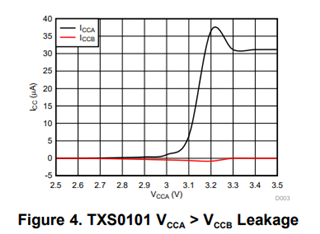

Have port A VDD connected to 3.3V and port B connected to 2.8V. Noticed that the spec says that VCCB >= VCCA. Since that's not the case, the spec is being violated. However, the part seems to be working most of the time. Occasionally, we get a bad I2C write to the downstream device (only one device connected to port B). Any idea why only sporadically we'd be getting a failure and not all the time? Why does the device have this limitation?