Dears

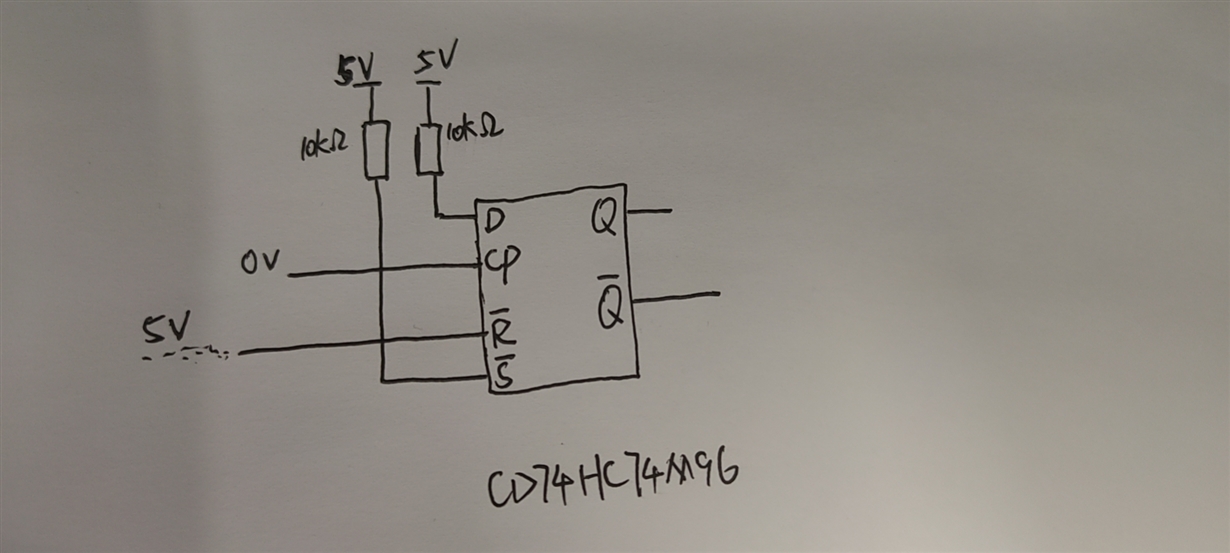

We are using a CD74HC74M96 D flip-flop chip. The wiring diagram is as follows.

After the chip is powered on, the ~R and ~S pins are both pulled high. According to the truth table, Q should output 0V. But after I touch the ~S pin with a conductive product, the Q pin of the chip will be set to 5V (5V power supply for the chip). After the chip is set, touch the ~R pin with a conductive product (such as an oscilloscope probe, or a pair of tweezers), and the chip Q is reset.

After the chip is powered on, the ~R and ~S pins are both pulled high. According to the truth table, Q should output 0V. But after I touch the ~S pin with a conductive product, the Q pin of the chip will be set to 5V (5V power supply for the chip). After the chip is set, touch the ~R pin with a conductive product (such as an oscilloscope probe, or a pair of tweezers), and the chip Q is reset.

I suspect it is the problem of the 10K pull-up resistor, but it still has this phenomenon after changing to a 2K resistor. After changing the 10K to 0Ω, the problem no longer recurs.

This is what I accidentally tested before.

After the product is subjected to an electrostatic test (the electrostatic gun is directed against the board panel, there is a discharge circuit on the panel), the 6KV electrostatic test board will be reset. Changing the pull-up resistor to 0Ω temporarily solved the problem, but it is not clear what causes the chip to be reset by conductive products, so I want to ask you When we design the circuit here, it is better to have a 10K or 100K resistor when pulling up all the chips to prevent the chip from breaking (such as a short circuit) and not directly killing the board.

I’m not sure if there is any weak pull-up on the internal input of the CD74HC74. I would like to consult you on this.