Other Parts Discussed in Thread: TMP117, INA233, , TM4C1230H6PM

Hello,

Reposting on this forum because it didn't seem to get much traction on the sensor forum.

(Using the TM4C1294NCPDTI3 to talk to TMP117).

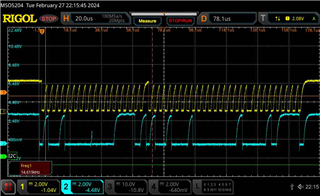

I am having I2C problems in which my i2c line seems to get stuck. The state where it's stuck is CLK held high and DATA held low.

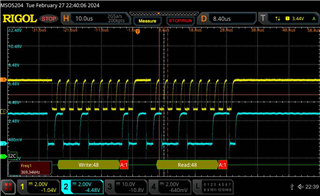

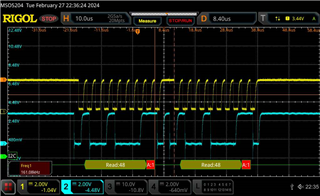

This has consistently happened after writing to the Configuration Register (01h) and reading back the 16-bit response. In the screenshots I took from the oscilloscope it looks like the data values are getting through but seem to have a problem getting the NACK and stop condition from the master. Is there any reason for this failure or how to avoid it? The problem is very inconsistent.

Other things to note are that are 4 INA233 on the i2c bus, an ADXL355BEZ accelerometer, and this TMP117 temperature sensor.

In all of the failures, the temperature sensor was always the peripheral that held the line.

YELLOW IS CLK

BLUE IS DATA

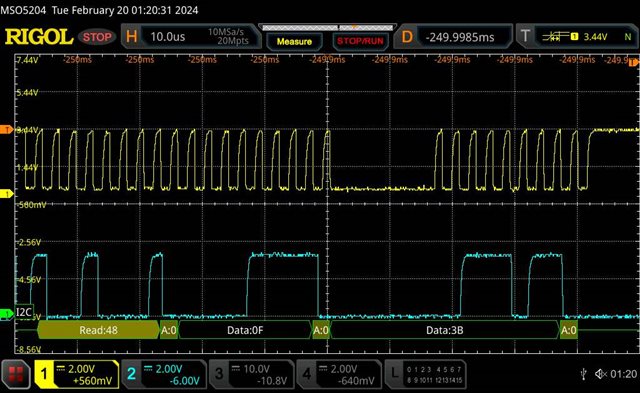

See failure waveform:

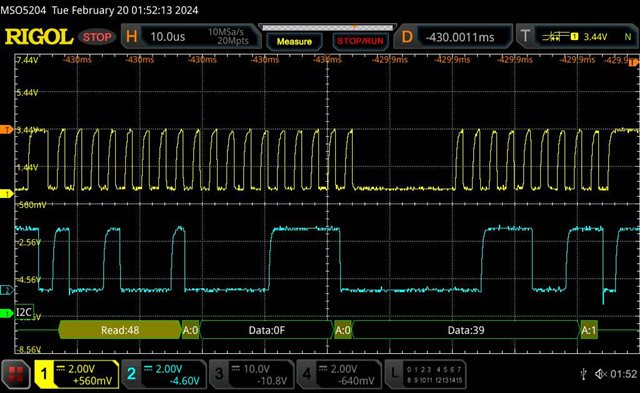

This is the successful transaction earlier in the loop:

Any ideas or advice would be helpful