Part Number: LP-AM243

Other Parts Discussed in Thread: BP-AM2BLDCSERVO

Tool/software:

Hi,

I have AM243x-LP and trying to read Biss-C singleturn 26 bit encoder. I use the following sample code. "C:\ti\motor_control_sdk_am243x_09_02_00_09\examples\position_sense\bissc_diagnostic\single_channel\am243x-lp"

Menu options are as follows;

#define BISSC_CMD_ENC_LOOP_OVER_CYC (5)

#define BISSC_CMD_PERIODIC_TRIGGER (6)

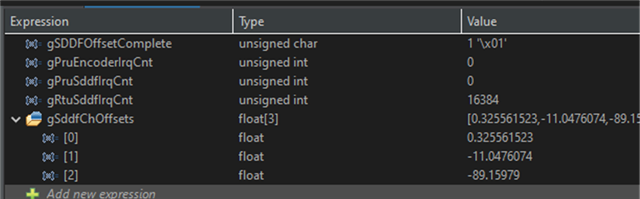

When I use (5), I get the Angle value

When I use (6) 12500 / 3000 for cmp* values, the code stuck at "ret = bissc_get_pos(priv);" in "int32_t bissc_get_pos(struct bissc_priv *priv)" funtion.

When I debug (5) and (6), I see very clear that (5) runs but (6) does not.

Regards,

Vedat