Hi,

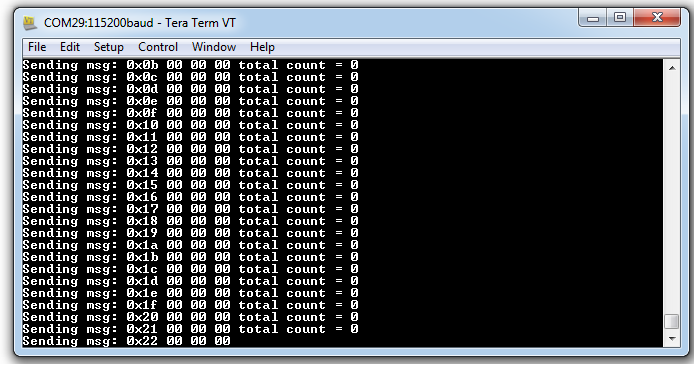

I am using CAN0 on the EK-LM4F232, and it works fine when I use PB4 and PB5. However, if I use PN0 and PN1 and PF0 and PF3, CAN0 doesn't seem to function. I have also checked the registers, and they are all set correctly. The following is the pin configuration for CAN0 and CAN0 configuration, does anyone know what I am missing?

================ Port B ================

ROM_SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOB);

ROM_GPIOPinConfigure(GPIO_PB4_CAN0RX);

ROM_GPIOPinConfigure(GPIO_PB5_CAN0TX);

ROM_GPIOPinTypeCAN(GPIO_PORTB_BASE, GPIO_PIN_4 | GPIO_PIN_5);

================ Port N ================

ROM_SysCtlPeripheralEnable(SYSCTL_PERIPH_GPION);

ROM_GPIOPinConfigure(GPIO_PN0_CAN0RX);

ROM_GPIOPinConfigure(GPIO_PN1_CAN0TX);

ROM_GPIOPinTypeCAN(GPIO_PORTN_BASE, GPIO_PIN_0 | GPIO_PIN_1);

================ CAN 0 Config. ================

ROM_SysCtlPeripheralEnable(SYSCTL_PERIPH_CAN0);

ROM_CANInit(CAN0_BASE);

ROM_CANBitRateSet(CAN0_BASE, 16000000, 1000000);

ROM_IntEnable(INT_CAN0);

ROM_CANIntEnable(CAN0_BASE, CAN_INT_MASTER | CAN_INT_ERROR | CAN_INT_STATUS);

ROM_CANEnable(CAN0_BASE);

CANConfigureNetwork();

Thank you

regards,

Kevin