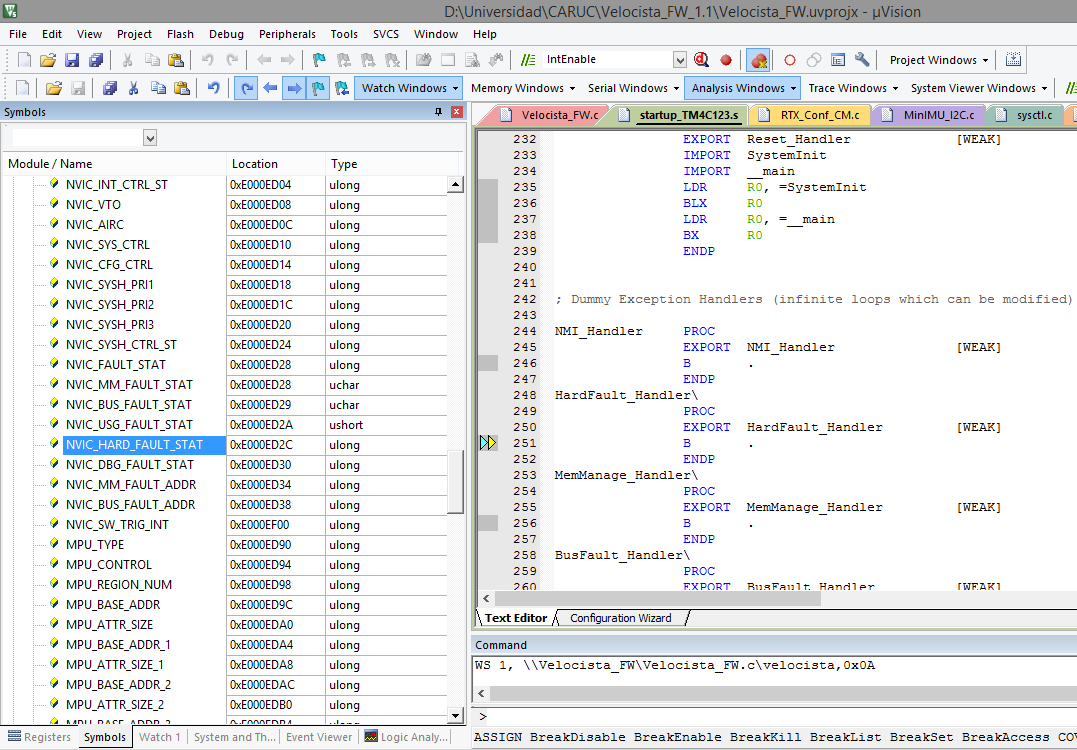

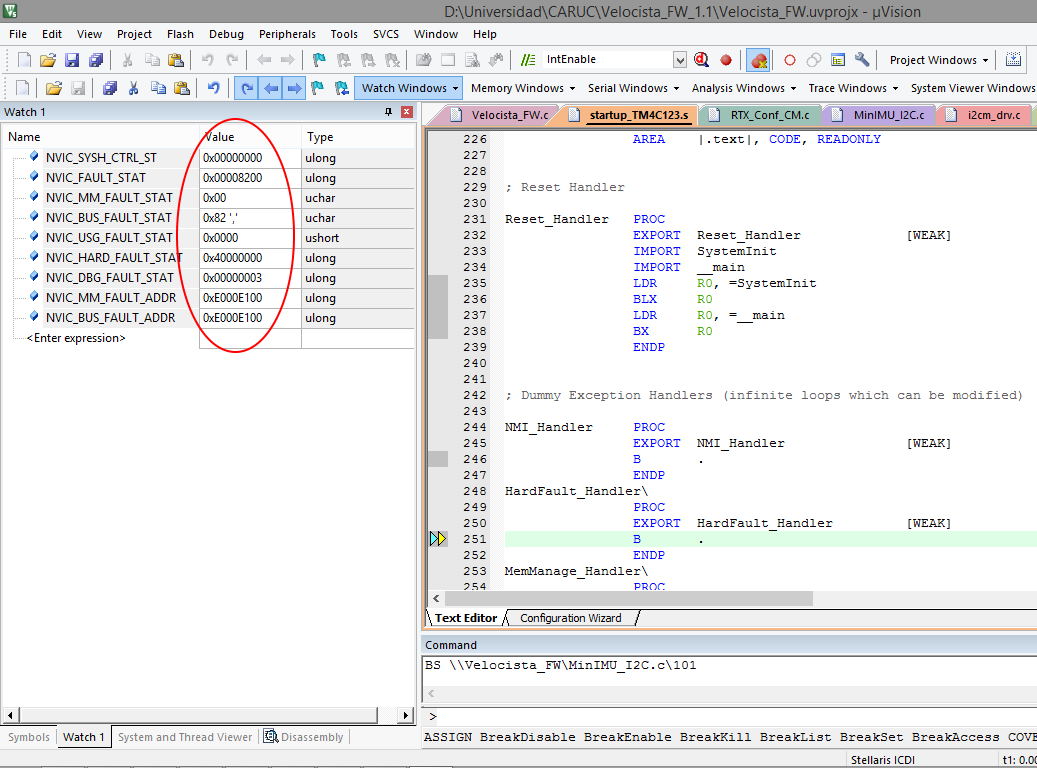

Hello, I'm using tiva c series prototiping board, and pololu minIMU V. 3.0 with L3GD20H - LSM303D sensors, communicating to I2C0 Bus, I'm using sensorlib drivers in code but this alwais go to HardFault_Handler, i'm using Keil uvision 5.12 and TivaWare_C_Series-2.1.0.12573 libraries, mi code its divided in tre steps, first task code, second general driver (in this use tivaware functions) and third tivaware drivers,

code for mi task

__task void Posicion(void){

//Inicializacion del canal de datos I2C

CNFG_I2CM_Init();

//Inicializacion del sensor de Giroscopio

//L3GD20H_Init();

//Inicializacion del sensor de Acelerometro y Magnetometro

LSM303D_Init();

while(1){

while(velocista.ctrl_sys1 != 0){

//Lectura de datos de los sensores de posicion

L3GD20H_Gyr_Read(&velocista.Pos_Gyro[0], &velocista.Pos_Gyro[1], &velocista.Pos_Gyro[2]);

LSM303D_Acc_Read(&velocista.Pos_Accel[0], &velocista.Pos_Accel[1], &velocista.Pos_Accel[2]);

LSM303D_Mag_Read(&velocista.Pos_Mag[0], &velocista.Pos_Mag[1], &velocista.Pos_Mag[2]);

//Pausa del sistema

os_dly_wait (2);

}

//Pausa del sistema

os_dly_wait (2);

}

}

this is the code for my driver, this is based in sensorlib user guide

#include "rtl.h"

#include "stdbool.h"

#include "stdint.h"

#include "TM4C123GH6PM.h"

#include "hw_memmap.h"

#include "i2cm_drv.h"

#include "lsm303d.h"

#include "l3gd20h.h"

#include "hw_l3gd20h.h"

#include "hw_lsm303d.h"

#include "sysctl.h"

#include "i2c.h"

/*--------------------------------------------------------------------------------

// Funciones requeridas para el funcionamiento del puerto I2C

--------------------------------------------------------------------------------*/

// The I2C master driver instance data.

tI2CMInstance g_sI2CMSimpleInst;

// A boolean that is set when an I2C transaction is completed.

volatile bool g_bI2CMSimpleDone = true;

// The interrupt handler for the I2C module.

void I2CMSimpleIntHandler(void){

// Call the I2C master driver interrupt handler.

I2CMIntHandler(&g_sI2CMSimpleInst);

}

// The function that is provided by this example as a callback when I2C

// transactions have completed.

void I2CMSimpleCallback(void *pvData, uint_fast8_t ui8Status){

// See if an error occurred.

if(ui8Status != I2CM_STATUS_SUCCESS){

// An error occurred, so handle it here if required.

}

// Indicate that the I2C transaction has completed.

g_bI2CMSimpleDone = true;

}

/*--------------------------------------------------------------------------------

Funcion 1 'CNFG_I2CM_Init' Configuracion de transmision por puerto I2C

--------------------------------------------------------------------------------*/

void CNFG_I2CM_Init(void){

// The I2C master driver instance data.

tI2CMInstance g_sI2CMSimpleInst;

// A boolean that is set when an I2C transaction is completed.

//volatile bool g_bI2CMSimpleDone = true;

// Set the clocking to run directly from the external crystal/oscillator.

// TODO: The SYSCTL_XTAL_ value must be changed to match the value of the

// crystal on your board.

SysCtlClockSet(SYSCTL_SYSDIV_10 | SYSCTL_USE_PLL | SYSCTL_OSC_MAIN |

SYSCTL_XTAL_16MHZ);

// Enable and initialize the I2C0 master module. Use the system clock for

// the I2C0 module. // I2C data transfer rate set to 400kbps.

I2CMasterInitExpClk(I2C0_BASE, SysCtlClockGet(), true);

//clear I2C FIFOs

//HWREG(I2C0_BASE + I2C_O_FIFOCTL) = 80008000;

// Initialize the I2C master driver. It is assumed that the I2C module has

// already been enabled and the I2C pins have been configured.

I2CMInit(&g_sI2CMSimpleInst, I2C0_BASE, INT_I2C0, 0xff, 0xff, 120000000);

}

///*--------------------------------------------------------------------------------

//Funciones requeridas para el funcionamiento del sensor L3GD20H

//--------------------------------------------------------------------------------*/

// A boolean that is set when a L3GD20H command has completed.

volatile bool g_bl3gd20hDone;

// The function that is provided by this example as a callback when L3GD20H

// transactions have completed.

void l3gd20hCallback(void *pvCallbackData, uint_fast8_t ui8Status){

// See if an error occurred.

if(ui8Status != I2CM_STATUS_SUCCESS){

// An error occurred, so handle it here if required.

}

// Indicate that the L3GD20H transaction has completed.

g_bl3gd20hDone = true;

}

///*--------------------------------------------------------------------------------

//Funcion 2 'L3GD20H_Init' Iniciaizacion del Giroscopio L3GD20H

//--------------------------------------------------------------------------------*/

void L3GD20H_Init(void){

//float fGyro[3];

tI2CMInstance sI2CInst;

tL3GD20H sl3gd20h;

// Initialize the L3GD20H. This code assumes that the I2C master instance

// has already been initialized.

g_bl3gd20hDone = false;

L3GD20HInit(&sl3gd20h, &sI2CInst, 0x68, l3gd20hCallback, 0);

while(!g_bl3gd20hDone){

}

// Configure the L3GD20H for 500 deg/sec sensitivity

g_bl3gd20hDone = false;

L3GD20HReadModifyWrite(&sl3gd20h, L3GD20H_O_CTRL4, ~L3GD20H_CTRL4_FS_M, L3GD20H_CTRL4_FS_500DPS, l3gd20hCallback, 0);

while(!g_bl3gd20hDone){

}

}

/*--------------------------------------------------------------------------------

Funcion 3 'L3GD20H_Read' Lectura de datos del Giroscopio L3GD20H

*--------------------------------------------------------------------------------*/

void L3GD20H_Gyr_Read(float* fGyro_X, float* fGyro_Y, float* fGyro_Z){

// A boolean that is set when a L3GD20H command has completed.

volatile bool g_bl3gd20hDone;

float fGyro[3];

tL3GD20H sl3gd20h;

// Request another reading from the L3GD20H.

g_bl3gd20hDone = false;

L3GD20HDataRead(&sl3gd20h, l3gd20hCallback, 0);

while(!g_bl3gd20hDone){

}

// Get the new gyroscope readings.

L3GD20HDataGyroGetFloat(&sl3gd20h, &fGyro[0], &fGyro[1], &fGyro[2]);

// Return Gyroscope values in poiter

*fGyro_X = fGyro[0];

*fGyro_Y = fGyro[1];

*fGyro_Z = fGyro[2];

}

/*--------------------------------------------------------------------------------

Funciones requeridas para el funcionamiento del sensor LSM303D

--------------------------------------------------------------------------------*/

// A boolean that is set when a LSM303D command has completed.

volatile bool g_bLSM303DDone;

// The function that is provided by this example as a callback when LSM303D

// transactions have completed.

void LSM303DCallback(void *pvCallbackData, uint_fast8_t ui8Status){

// See if an error occurred.

if(ui8Status != I2CM_STATUS_SUCCESS){

// An error occurred, so handle it here if required.

}

// Indicate that the LSM303D transaction has completed.

g_bLSM303DDone = true;

}

/*--------------------------------------------------------------------------------

Funcion 4 'LSM303D_Init' Iniciaizacion del Acelerometro y Magnetometro LSM303D

--------------------------------------------------------------------------------*/

void LSM303D_Init(void){

// A boolean that is set when a LSM303D command has completed.

volatile bool g_bLSM303DDone;

tI2CMInstance sI2CInst;

tLSM303D sLSM303D;

// Initialize the LSM303D. This code assumes that the I2C master instance

// has already been initialized.

g_bLSM303DDone = false;

LSM303DInit(&sLSM303D, &sI2CInst, 0x68, LSM303DCallback, 0);

while(!g_bLSM303DDone){

}

// Configure the LSM303D for +/- 4 g accelerometer range.

g_bLSM303DDone = false;

LSM303DReadModifyWrite(&sLSM303D, LSM303D_O_CTRL2,~LSM303D_CTRL2_AFS_M, LSM303D_CTRL2_AFS_4G, LSM303DCallback,0);

while(!g_bLSM303DDone){

}

}

/*--------------------------------------------------------------------------------

Funcion 3 'LSM303D_Acc_Read' Lectura de datos del Acelerometro LSM303D

*--------------------------------------------------------------------------------*/

void LSM303D_Acc_Read(float* fAccel_X, float* fAccel_Y, float* fAccel_Z){

// A boolean that is set when a LSM303D command has completed.

volatile bool g_bLSM303DDone;

float fAccel[3];

tLSM303D sLSM303D;

// Request another reading from the LSM303D.

g_bLSM303DDone = false;

LSM303DDataRead(&sLSM303D, LSM303DCallback, 0);

while(!g_bLSM303DDone){

}

// Get the new accelerometer readings.

LSM303DDataAccelGetFloat(&sLSM303D, &fAccel[0], &fAccel[1], &fAccel[2]);

// Return accelerometer values in poiter

*fAccel_X = fAccel[0];

*fAccel_Y = fAccel[1];

*fAccel_Z = fAccel[2];

}

/*--------------------------------------------------------------------------------

Funcion 4 'LSM303D_Mag_Read' Lectura de datos del Magnetometro LSM303D

*--------------------------------------------------------------------------------*/

void LSM303D_Mag_Read(float* fMag_X, float* fMag_Y, float* fMag_Z){

// A boolean that is set when a LSM303D command has completed.

volatile bool g_bLSM303DDone;

float fMag[3];

tLSM303D sLSM303D;

// Request another reading from the LSM303D.

g_bLSM303DDone = false;

LSM303DDataRead(&sLSM303D, LSM303DCallback, 0);

while(!g_bLSM303DDone){

}

// Get the new magnetometer readings.

LSM303DDataMagnetoGetFloat(&sLSM303D, &fMag[0], &fMag[1], &fMag[2]);

//

// Return accelerometer values in poiter

*fMag_X = fMag[0];

*fMag_Y = fMag[1];

*fMag_Z = fMag[2];

}

finali in debug i'm detect the code that generate the hardfault esception

in line:

I2CMInit(&g_sI2CMSimpleInst, I2C0_BASE, INT_I2C0, 0xff, 0xff, 120000000);

function go to enable interrupt in file i2cm_drv.c

MAP_IntEnable(ui8Int);

and finaly execute this code in interrupt.c

//

// Enable the general interrupt.

//

HWREG(g_pui32EnRegs[(ui32Interrupt - 16) / 32]) =

1 << ((ui32Interrupt - 16) & 31);

and go to hardfault exception

and the rebuild not generate errors

Thanks for your help !!