Other Parts Discussed in Thread: TMDSHVMTRINSPIN, C2000WARE

Hi TI team,

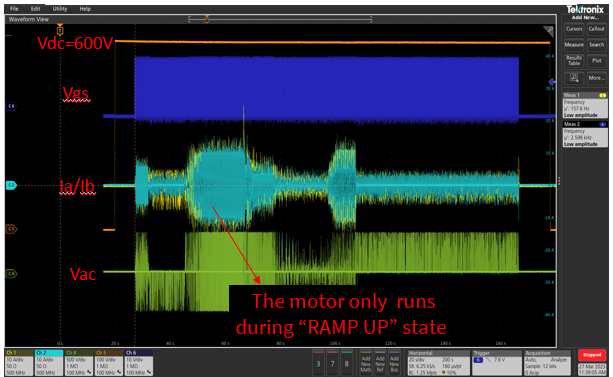

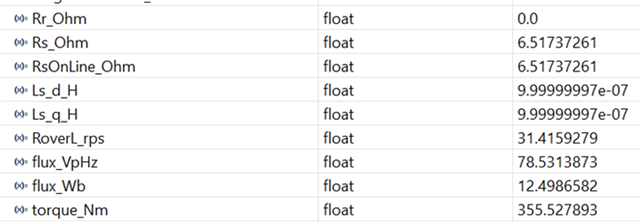

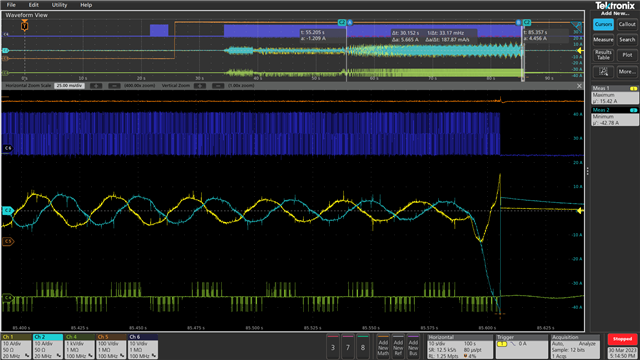

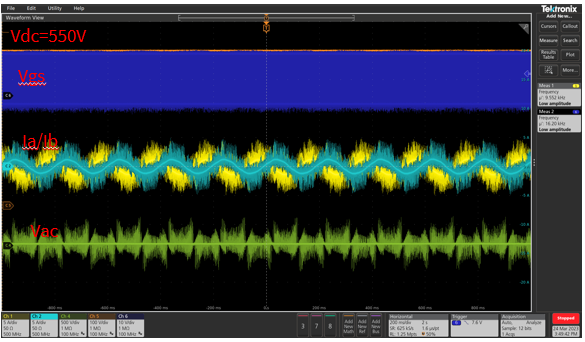

I'm debugging the motor control with TMDSHVMTRINSPIN in C2000Ware_MotorControl_SDK_4_00_00_00. My motor's rated parameters are: 320V, 38A, 3000rmps, 200Hz. Now I'm trying to run the motor with lab7. As my understanding, it should start with a constant current under forcedangle mode ro run the motor. After the motor can runs at a certain speed, then we can add the speed close loop by the command"motorVars.flagEnableForceAngle=0 ". I'm not sure whether my understanding is right or not. If so, how and where can I change the start up current? My motor's inertia is much larger than the kit's. As the following waveform shown, the motor cannot run with the orignal start up current(forced frequency 5Hz). But I didn't find how to increase this current. Would you please help on this? Looking forward to your reply. Thank you very much!

Best regards,

Iris Liu