Hi,

I'm working on a single-phase inverter based on the TIDM-HV-1PH-DCAC demo board. The system seems to work, but randomly, my transistors break on start-up. I'm in a closed voltage/current loop. The system works on resistive loads at maximum power and the breakage does not depend on the load.

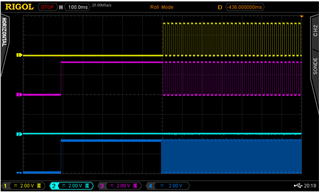

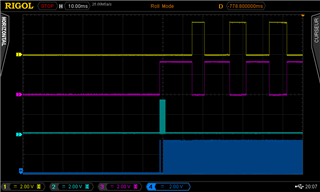

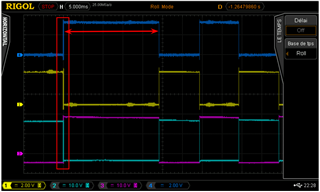

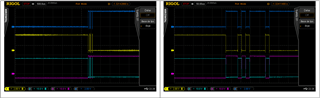

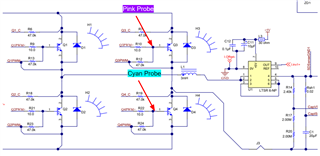

After searching for the cause of the problem, it turns out that the transistors, which switch at 50Hz, are erratically controlled at start-up. I've attached screenshots of the phenomenon:

Zoom in on the framed area:

The arrangement of the probes is as follows:

The blue probe corresponds to the control of transistor Q1 on the microcontroller.

The yellow probe corresponds to the control of transistor Q2 on the microcontroller.

The pink probe corresponds to the command taken on the gate of Q1.

The yellow probe corresponds to the command taken from the gate of Q2.

My hypothesis is that the problem could come from PWM initialization, maybe they're started before initialization?

Do you have any idea how to solve this problem?

Thank you very much!