- Ask a related questionWhat is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Dear team:

A customer of mine has abnormalities in the motor when running lab11e. The motor can run normally when it is rotating, but it cannot be switched to reverse. Moreover, when the motor is reversing or at low speed, it will get stuck and vibrate. The following are the motor parameters (data from lab03a):

//! \brief USER MOTOR & ID SETTINGS #define MY_MOTOR 113 //#define USER_MOTOR HighCurrent_LowInductance #define USER_MOTOR MY_MOTOR #elif (USER_MOTOR == MY_MOTOR) #define USER_MOTOR_TYPE MOTOR_Type_Pm #define USER_MOTOR_NUM_POLE_PAIRS (2) #define USER_MOTOR_Rr (NULL) #define USER_MOTOR_Rs (0.878300548) #define USER_MOTOR_Ls_d (0.00130555173) #define USER_MOTOR_Ls_q (0.00130555173) #define USER_MOTOR_RATED_FLUX (0.0330096558) #define USER_MOTOR_MAGNETIZING_CURRENT (NULL) #define USER_MOTOR_RES_EST_CURRENT (1.0) #define USER_MOTOR_IND_EST_CURRENT (-1.0) #define USER_MOTOR_MAX_CURRENT (3.0) #define USER_MOTOR_FLUX_EST_FREQ_Hz (20.0) // this section defined in user_j1.h or user_j5.h

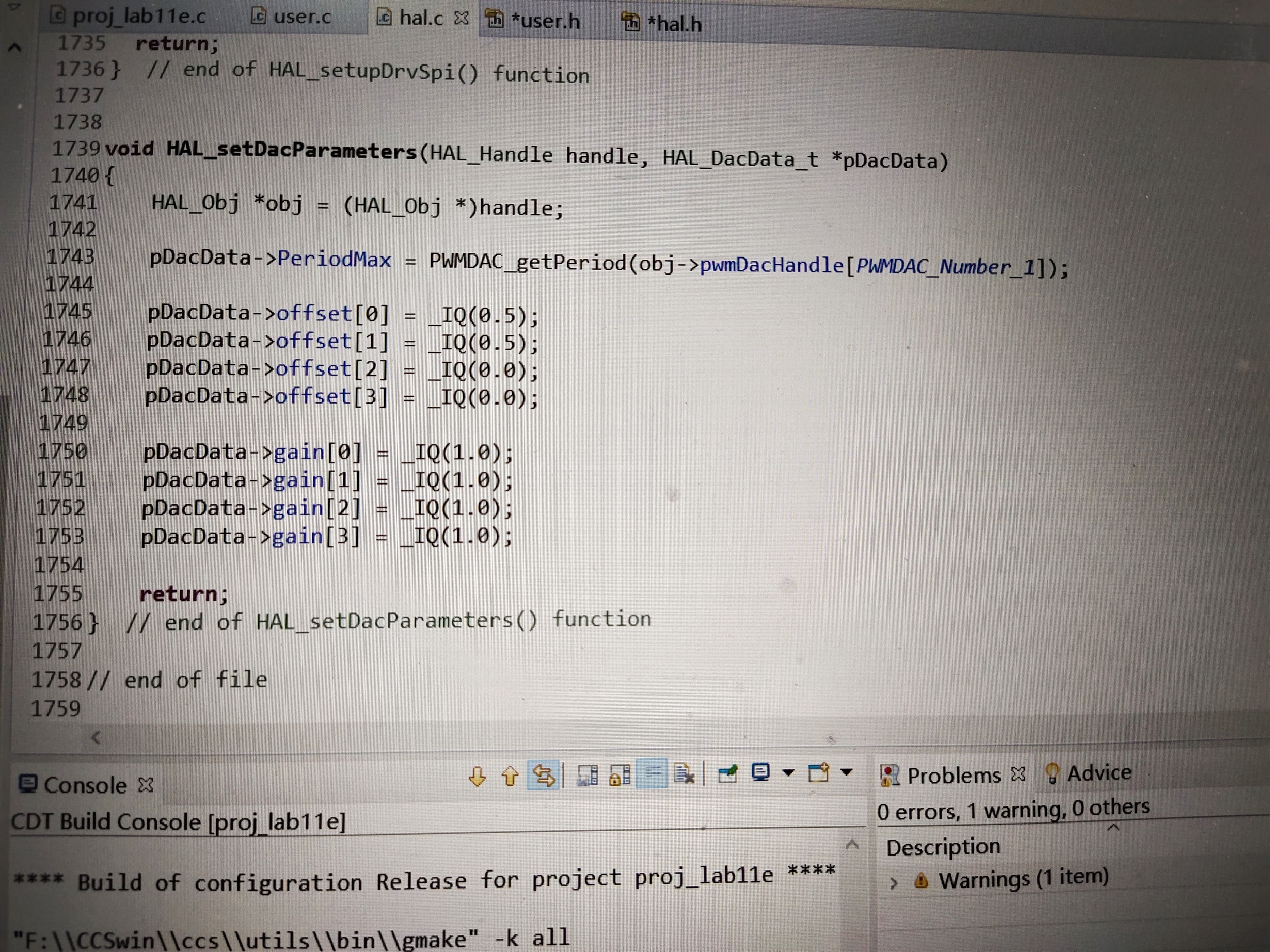

Is this related to the settings of “offsets”?

Best Regards

Lab11e uses a hall sensor for low speed and startup.

1. Does the customer connect the hall sensor and configure the hall commutation index correctly?

2. Does the customer tune the torque current for low speed based on the motor?

3. Does the customer stop the motor before switch to a reverse rotation?

Hi Yanming:

Thank you for your reply. As this is a Chinese customer, I will communicate with you directly in Chinese.

以下是客户回复:

霍尔传感器连接是正确的,这个霍尔换向系数是在哪里配置啊

低俗转矩电流怎么调整呢。

您是指把Flag_run_identify置为0来停止呢,还是指把SpeedRef_krpm写0来停止呢,如果是前者的话我是实现了反转的,但是后者,就是在Flag_run_identify为1的前提下,想要置SpeedRef_krpm为0电机就停不下来。

请问,如果说TI内部的算法内部也是先把Flag_run_identify置0,再把SpeedRef_krpm写为反向的吗,还是说其他方法啊。

In addition, if time permits, please help follow this post from E2EChina on InstaSPIN-FOC:

https://e2echina.ti.com/question_answer/microcontrollers/c2000/f/56/t/198957

Best regards

1. Please ensure the sequence of the hall input signal is corresponding to the set number in gHall_PwmIndex[].

2. You may increase PWM frequency if possible because the Hall signal is detected in PWM ISR. The delay time will have an impact on the high speed running if the PWM frequency is too low.

3. Tune gHall2Fast_Spd_Coef, gHall2Fast_Iq_coef, gHall_speed_FastToBldc_low_pu and gHall_speed_BldcToFast_high_pu.

4. Tune the gains of the PI regulator in HALLBLDC_Ctrl_Run().

You or your customer might take a look at the following threads about lab11e

https://e2e.ti.com/support/microcontrollers/c2000/f/171/p/883444/3294852

https://e2e.ti.com/support/microcontrollers/c2000/f/171/t/670979

https://e2e.ti.com/support/microcontrollers/c2000/f/171/t/883444

https://e2e.ti.com/support/microcontrollers/c2000/f/171/p/822522/3043645