Hello,

I am trying to built a water meter sensor using the using MSP30FR6047EVM rev 2 and a DN25 pipe in which the distance of the transducers is about 80mm and I have some questions.

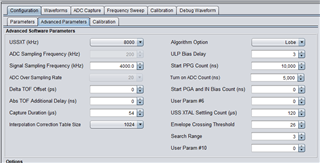

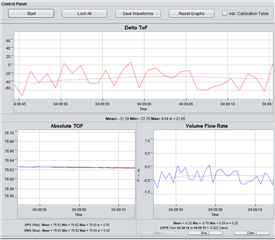

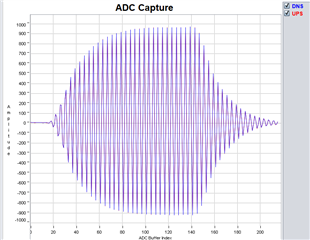

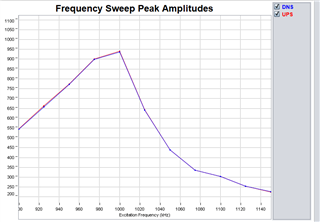

1. Are the below settings and adc capture good? Do I need to make any changes?

2. After I finish with the configuration of the evm, I will pass the configuration settings into a custom MSP30FR6047 board which has the same pipe and transduser distance. Except of the meter constant and the meter calibration parameters, is there anything else that needs to be changed?