Other Parts Discussed in Thread: TIDA-01486

Tool/software:

Hi everyone,

I’ve successfully measured through PVC pipes with good results, but I understand that working with stainless steel (SS) pipes is more challenging due to signal attenuation.

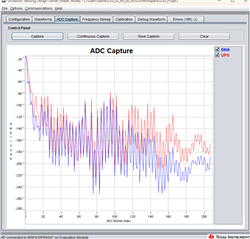

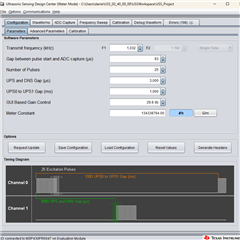

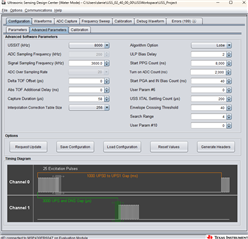

Currently, I’m experimenting with an 85mm stainless steel pipe. I believe I’ve identified the “correct” signal lobe. Specifically, I’m seeing a lobe at 29 μs after the start pulse, which I suspect corresponds to excitation pulses traveling along the pipe walls.

Additionally, I’ve observed a later lobe at 93 μs. However, this signal is very weak and not consistently repeatable.

To improve the results, I enabled the USS_ALG_CALIBRATED_DNS_DC_OFFSET setting as suggested in another thread, since achieving a strong gain appears to be crucial in this case.

Does anyone have tips or tricks to improve signal strength or measurement accuracy for stainless steel pipes? Any advice is appreciated!