Other Parts Discussed in Thread: TIDA-01486

Tool/software:

Hi everyone, thanks a lot for all the help you guys gave me in the last thread, all in all I can now get the TIDA-01486 working well with the evm430fr6047.

I'm now working on the traffic stability issue, and I have to say that TI's traffic algorithm works very well, but I'm having some problems with the parameter “Gap between pulse start and ADC capture”.

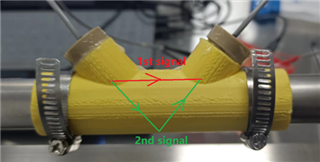

First of all to describe my measurement environment, I use a V-type external clamp mount on ppr pipes, so there will always be some signal propagating along the pipe rather than through it, like below.

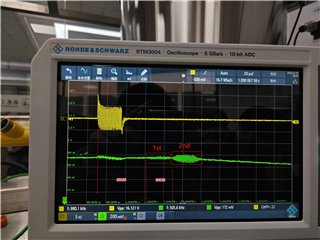

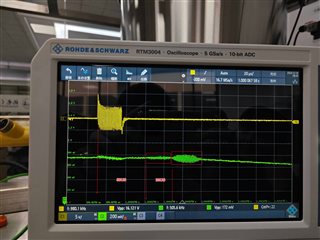

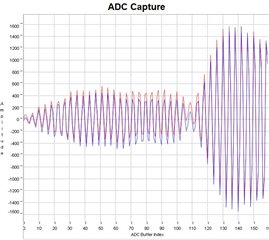

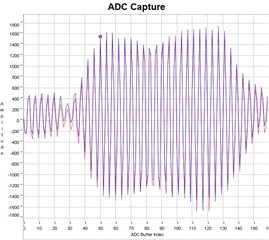

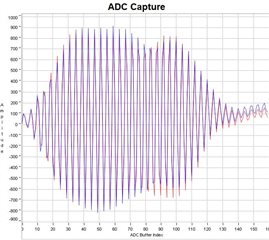

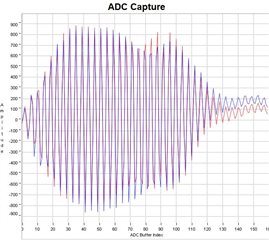

As you can see, and this is proven on the oscilloscope, it seems to me that it is only the back flap that carries the flow information.In the captured waveform of the OP, I can't guarantee that there is a 0 offset waveform in the captured waveform due to the presence of the previous waveform, which doesn't match TI's requirements, like the following.The following figures show the waveforms with “Gap between pulse start and ADC capture” set to 50us and 70us, respectively.

I tried hard to remove the effect of the previous waveform by changing the value of “Gap between pulse start and ADC capture”.

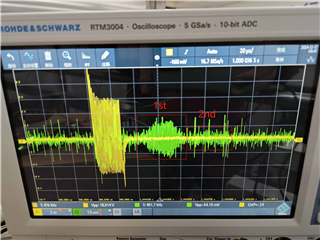

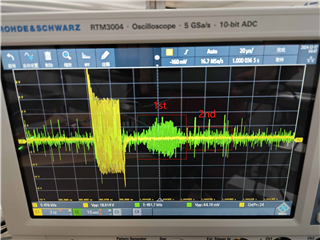

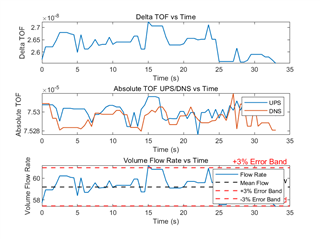

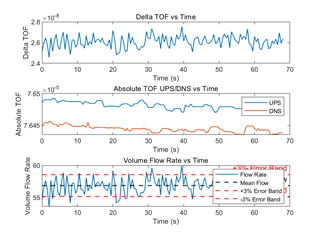

I tried to eliminate the effect of the previous waveform, by changing the value of “Gap between pulse start and ADC capture”, I found that the stability of the flux calculation is very different with only 1us difference in this parameter, for example, the following graphs are 74us and 75us for this parameter respectively. For example, the following graphs show the waveforms and the flow calculation for 74us and 75us, respectively, and you can see that there is a very big difference, which is a disaster for our design, and we can't determine a good parameter.

It is worth noting that they were all measured in the same measurement environment and at the same flow rate, even with no more than five minutes between the start of measurements

So here's my question.

1. what is the difference between these two waveforms from the point of view of the ti algorithm and why are they so different

2. we tried to modify the parameters in the algorithm, such as the threshold for the capture algorithm and things like that, but couldn't get anywhere, can you give some advice?

3. For a V installation, only the latter waveform is really the propagating waveform in the water flow. Am I understanding this correctly as we can barely see the rear waveform in stainless steel piping and I would like to confirm this

Any reply I will be very grateful!

Best Regards