Other Parts Discussed in Thread: MCT8316Z, MSP430FR2000, MSP430FR2111

Hi team,

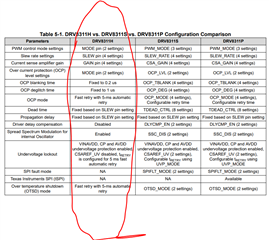

I’ve got two questions on DRV8311. Could you please take a look below, and help me understand this device more?

Q1: In my understanding, DRV8311H can be used without MCU since it has hardware interface. Is it still possible to use as sensored (meaning with current sensor) without MCU?

Q2: SPI is used for accessing the registers , right? Is there any other functions for SPI?

Best regards,

Kurumi