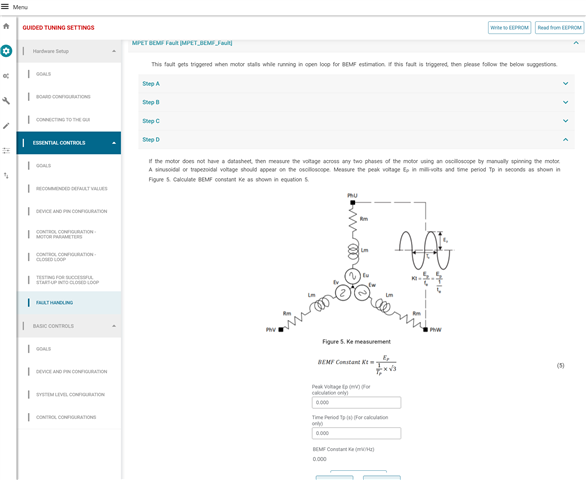

While following the "Essential Controls" guide section of the GUI, I get a MPET_BEMF_FAULT after the motor twitches. This result is not consistent; occasionally other faults will be triggered, the MPET algorithm will idle forever without doing anything, or nothing will happen at all. I have tried manually calculating the motor characteristics, but it doesn't seem to function correctly, or will trigger additional faults.

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.