Other Parts Discussed in Thread: , DRV8428

Dear Expert,

Hi, my name is Byeongsu, Kang, and i am in charge of electrical circuit and control for ACS module.

I'm looking for a way to reduce jitter performance such as audio noise or control error in a stepper motor. The motor specifications are as follow;

- Nominal Voltage : 12 V

- Resistance : 180 ohm

- Inductance : 90 mH

- Step Size : 1.8 degree

- Gear Box : 1:35 and 1:3.2

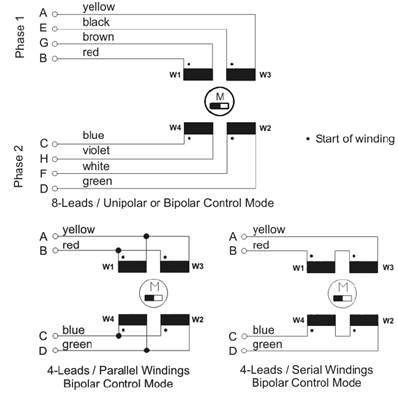

- Connection : 4 leads Serial Windings Bi-polar

I was found the DRV8426 part and perform the primary functional test using DRV8426EVM. The setting parameter are as follow;

- Software : DRV84xx EVM

- Control Mode : Step

- Step Mode : 1/256 step

- VREF Voltage : 0.16 V

- Speed : 8000

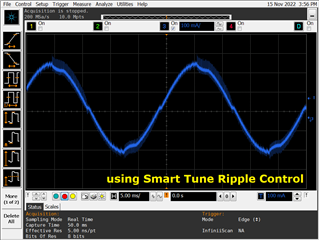

- Decay Mode : Smart Tune Ripple Control

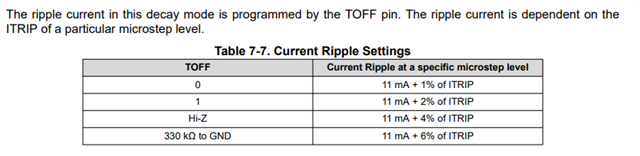

- TOFF : 300 kohm to GND

- VM : 12 V

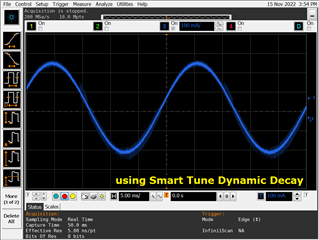

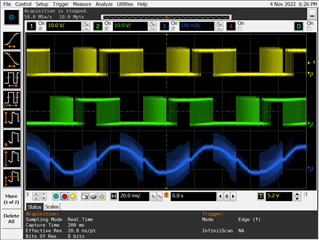

I got the following result using the oscilloscope, yellow line is output voltage of AOUT1, green line is output voltage of BOUT1 and blue line is output current of AOUT1.

I was control the value of VREF to reduce jitter performance, and this result is one of the best. However, I want to reduce jitter performance more.

Q1. is DRV8426 is suitable solution to control the above motor?

Q2. How to reduce the high frequency factor in the blue line (Current Output)? Does this factor affect the jitter performance?

Q3. I can change the motor connection to 4 leads parallel winding bi-polar. I guess that specifications were changed as follow;

- Resistance : 45 ohm

- Inductance : 22.5 mH

If i change the connection from serial to parallel, the jitter performance to be better or not?

Could you help me to solve this issue?

Thanks & Best Regards,

Byeongsu, Kang