Other Parts Discussed in Thread: MCT8316A, MCF8316A, MCT8316Z

Dear community,

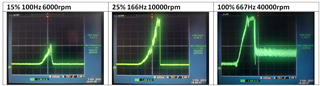

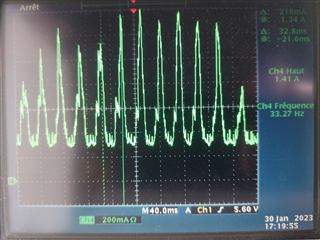

- During the tuning of the MCF8316AEVM, I found that when the PI controller is not well adapted, the motor under load is vibrating at a fix shaking frequency (around 30Hz) with these following visible current peaks on the main VM wire:

This vibrating behavior disappears if the PI settings are not so agressive.

What is the source of this frequency? Is it the PI controller treatment period? This value is fix, even if I change any settings, pwn frequency or speed.

If it comes from a setting register, it would be interesting to increase this frequency in order the PI controller reacts faster and adapt better the speed and torque.

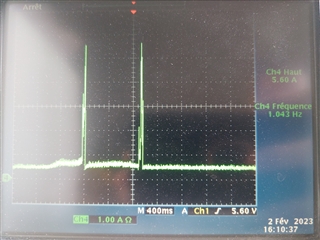

- Also, sometimes, when I start or stop the motor, it presents rough 8A short overshoots on the main (VM wire) current:

<=== here a start followed by a stop, motor is rotating between both overshoots

<=== here a start followed by a stop, motor is rotating between both overshoots

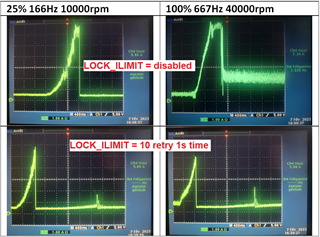

How to prevent these peaks?

I have the feeling that these peaks are generated when we switch from open loop to closed loop and closed loop to brake procedure.

When the PI controller values are set manually the peaks behavior seems higher than when Ki Kp values are 0 and auto tuned, then the peaks are less often present and limited by the ILIMIT current value. Where can we read the auto tuned Ki Kp values?

Thank you in advance. My motor parameters are: 24VDC, 40.000rpm max, 1.35R, 0.09mH, 17mV/Hz (from MPET), 8.2A stall current.

Best Regards,

Julien