What are the circumstances in which a DRV8220 DSG blows up?

A prototype PCB that controls a 600mA brushed dc motor uses a DRV8220 DSG to drive the motor in PWM mode at 100% duty cycle, and I managed to blow the driver up in what I think is normal operation! Was not paying too much attention to the circumstances when I heard a small pop after which the case of the driver had a hole in a place where previously there was none. Suffice to say, the driver no longer produces output. The motor was continuously moving in the same direction for some tens of seconds. Supply voltage was 12V. Half a minute later the board did not feel hot (didn't think to touch it any sooner). Board generally gets warm but not hot.

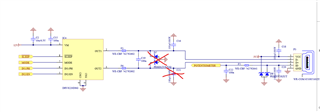

In the schematic we also included a ESD protection which is not present in the proto

If you can provide some suggestions for the next revision of our hardware, that would also be great?

See here the schematic and the physical print after the incident.