Other Parts Discussed in Thread: BOOSTXL-DRV8323RS

Hi,

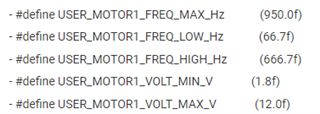

I'm trying to fix up LAUNCHXL-F2800137 and BOOSTXL-DRV8323RS eval kit together to drive a 12V BLDC motor. This BLDC motor is an off-the-shelf part, not recommended in TI's application notes.

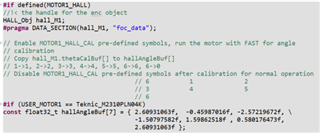

Currently I'm stuck at DMC_BUILDLEVEL DMC_LEVEL_2. My BLDC motor just keep cogging when I set "motorVars_M1.flagEnableRunAndIdentify" to 1.

I just wish to check what's the parameters in user_mtr1.h that I need to modify correctly in order to make my customized BLDC motor to rotate continuously when DMC_BUILDLEVEL is set to DMC_LEVEL_2.

Hope to hear from you soon.

Regards,

Yip Kok Loong