Other Parts Discussed in Thread: CSD88584Q5DC, DRV8306,

Hi,

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Hi,

Hi Adam,

Can you check the voltage of the VCP pin, it should be roughly equal to VM+10V?

Does the fourth unit's nFAULT pin get pulled low when attempting to drive the motor?

Regards,

Joshua

Hi Joshua,

Thanks for the response!

VCP is VM+10V (34V) - I checked on two of the faulty units so far, both were the same.

nFAULT pin does not get pulled low when attempting to drive motor on fourth unit.

Any ideas?

Hello Adam,

Have you preformed an ABA swap of the DRV8306 to see if the issue follows the DRV8306 or the board?

Can you also provide a capture of GHx, GLx, SHx, and the input PWM for both of the DRV8306s on the fourth unit when going from brake mode into spinning the motor?

Regards,

Joshua

Hi Joshua,

No I haven't tried an ABA swap, I don't have experience soldering SMT - but seems it might be time to learn.

I'll get the requested captures and get back to you, this will likely be early next week.

Thanks again and let me know if you have any other thoughts.

Adam

Hi Joshua,

Hello Adam,

There does seem to be an issue with the motors hall signals to the DRV8306 either internally or from the board.

What voltage is being used for the pull-up resistor on the HPx pins, assuming you are using digital hall sensors?

For both Fault conditions, can you provide a capture of the hall signals as close to the HPx pins of the DRV8306 as possible?

For the devices experiencing Fault Condition 1, what voltage is being output by DVDD? IF DVDD is not outputting 3.3V can you try supplying the ENABLE pin with 5.5V and check DVDD again?

Regards,

Joshua

Thanks yet again Joshua.

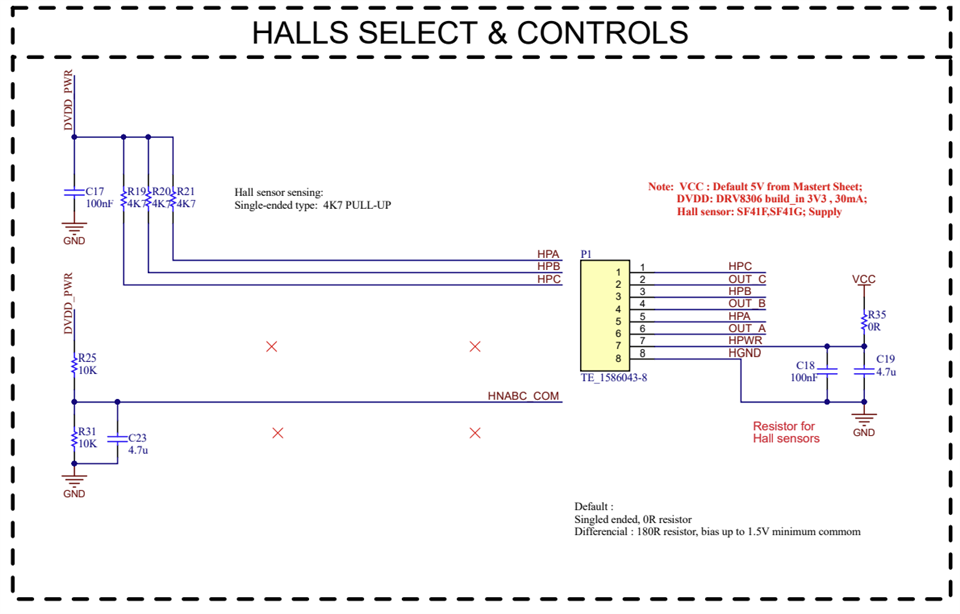

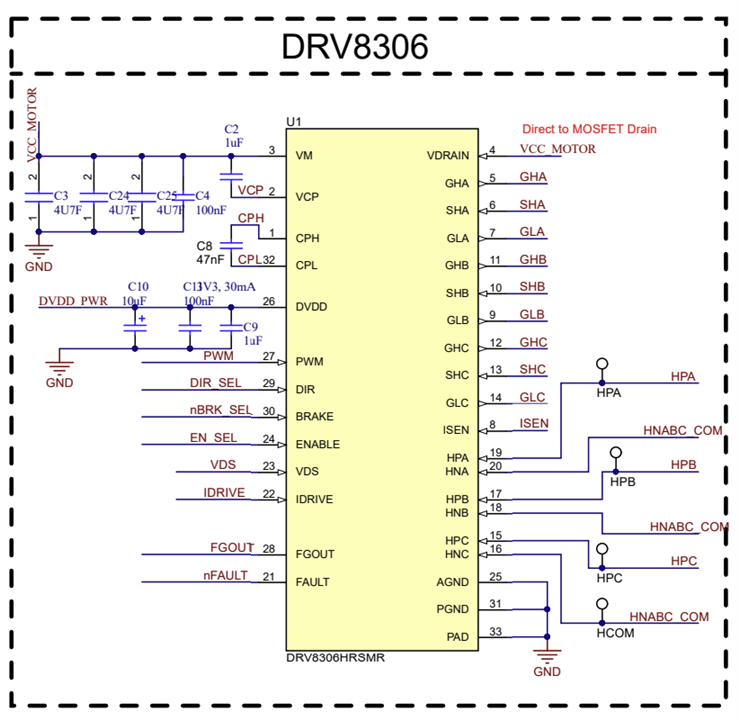

Below is our hall + DRV8306 circuits. As shown HPx pins are pulled up to DVDD via 4.7K resistors. Also DVDD on all faulty boards was 3.3V when I checked initially. I will double-check this though. I can capture the hall signals close to HPx pins as we have test points right there.

Hi Joshua,

DVDD was 3.3V on rechecking (or very close to that). Below are some captures of the hall signals + PWM. Sorry for the photos, this is a new scope which arrived today, so didn't have time to learn the capture process :)

This side has fault condition 2. I tried to capture the change when it goes into fault, but no success yet.

Below is a 'normal' unit

As shown there are pulses from the PWM signal appearing on the hall signals (when the signals are high). These pulses are higher on some signals compared to others. One difference between the fault unit and a normal unit, is these higher pulses are more consistent throughout the high signal.

Please let me know if you have any feedback on this.

Hi Adam,

Please allow me some time to look into this. I will aim to get back with you by Wednesday of next week.

Regards,

Joshua

Hi Joshua,

That is completely fine, thanks for taking the time to look into this further.

I just wanted to include the below captures to potentially assist. These are all from a side has fault condition 2.

1. Hall effect signals at motor stop

HPA=CH1, HPB=CH2, HPC=CH3, FGOUT=CH4

These we captured by first going to the bad spot (HPA=0,HPB=0,HPC=1), then moving the motor back to the previous position (HPA=0,HPB=1,HPC=1). So on the next start, the motor moves briefly then stops. As shown, at times it will stop straight on 'bad', and others it moves briefly to the next position, then back to 'bad'. Note: our system has a soft ramp-up to start the motor. If I made this ramp faster or removed it - the motor would then start from the position before the bad spot i.e. it would then only not start if actually on the bad spot.

Stop on bad:

Stop on bad after brief move to next position:

Spinning (with what looks like a rough start-up)

2. GHx signals

GHA=CH1, GHB=CH2, GHC=CH3, FGOUT=CH4 (all wrt GND)

As shown GHx signals are not correct - the 'GHx=24V' fault is occurring repeatedly throughout the commutation process. I also noticed the motor pulling higher than normal current.

Commutation on fault 2 side:

Failed start (stopped on bad spot):

Good unit for reference:

Hi Adam,

In the captures that you provided the hall signal on channel 1 exceeds the absolute maximum value for the HPx and HNx pins which is DVDD (~3.3V). The absolute maximum value violation may have lead to internal damage within the device.

I would recommend placing a capacitor, with a value between 1nF to 100nF, between the HPx and HNx traces to try and mitigate the noise being coupled onto the hall signals.

Regards,

Joshua

Hi Joshua,

Thanks for your input. I agree the noise is an issue, it is being coupled from the phase to the hall signals in the multicore cable going to the motors. We have started testing with capacitors as suggested and it removed the noise. We need to do more testing though as the 100nF cap we started with added a curve to the hall effect signal as shown below. So we will do more testing with different values and then implement this on the board as an update.

I'm still puzzled by the fault though. All units I've tested (good and failed) show this noise. However, we have +350 boards in the field, some for several years now - with no faults. We also successfully conducted a +1M cycle life test before launching this product range. Then in this one batch of 8 boards, 4 failed within the first month. This week we started a new life test to be sure, and it is already well past where these units failed. So I think the noise is involved, but something to do with these particular units made them more susceptible.

Anyway, I'll close this as resolved for now....and will update later if something of interest comes up. Thanks for all your help Joshua.