Hello,

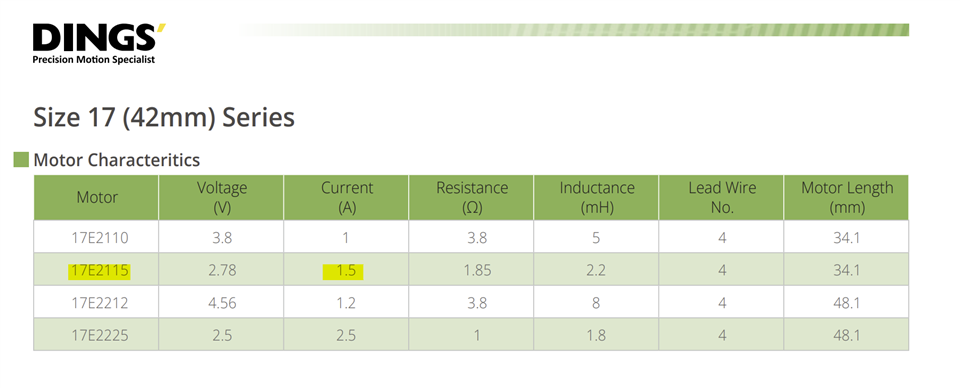

I am using DRV8462 to control stepper motors DINGS 17E2115AB4-69SNSN-130.

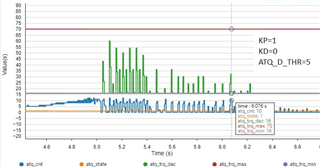

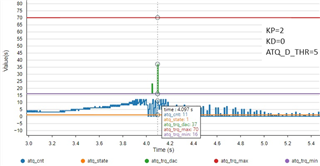

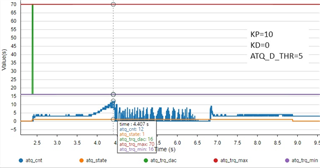

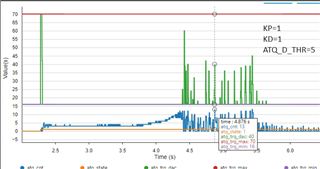

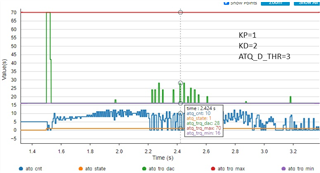

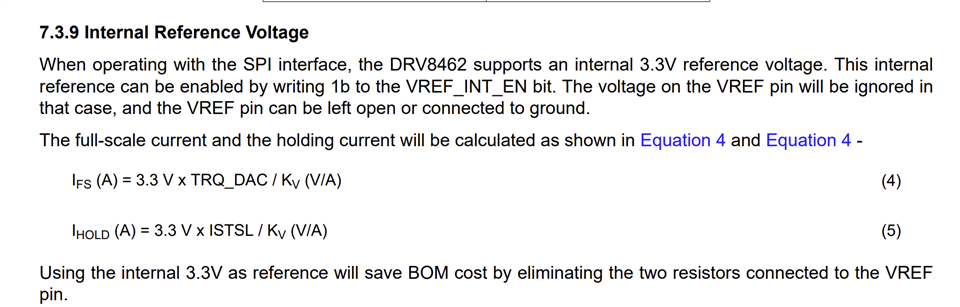

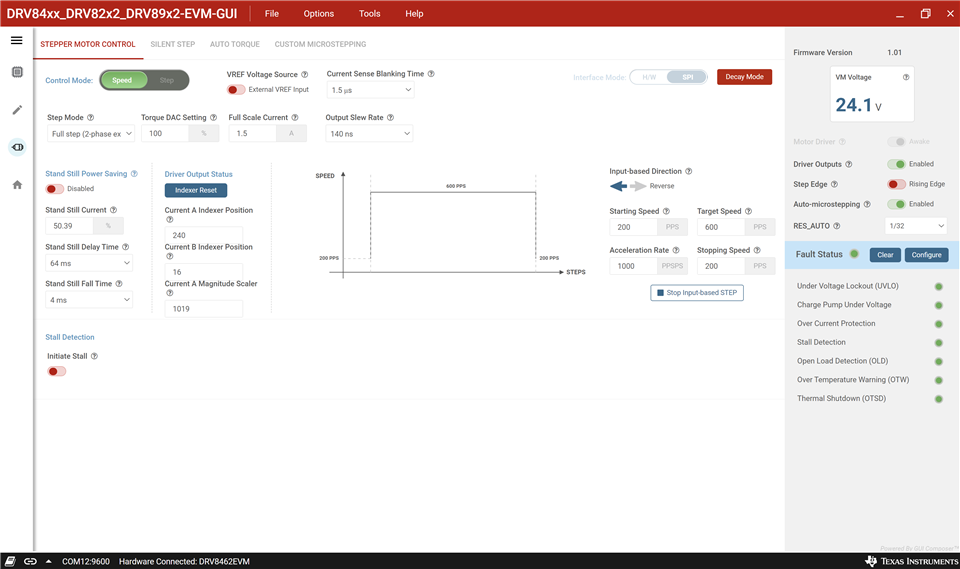

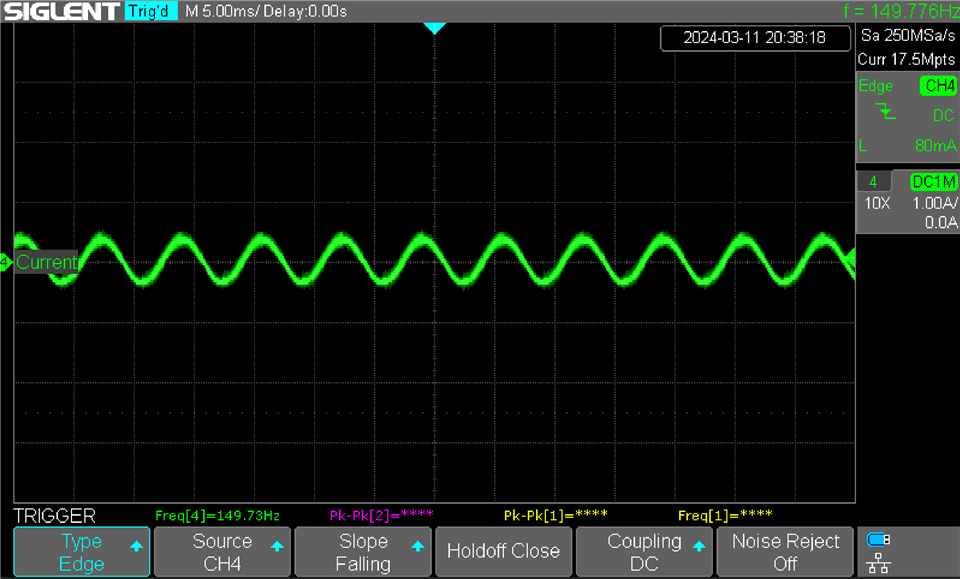

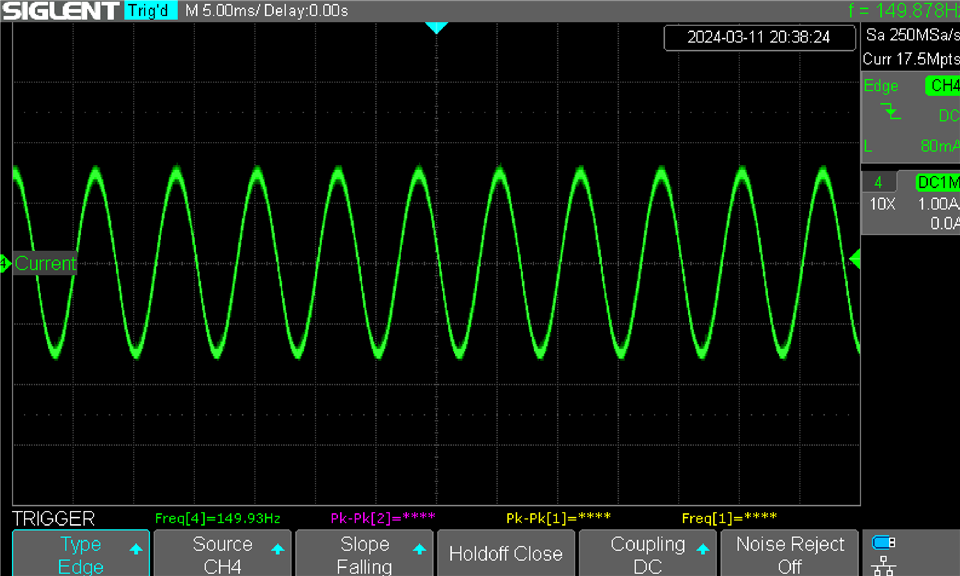

The supply voltage is 24V. I use physical STEP and DIR pins and control other registers via SPI. The motors run with full step and automatic 1/32 microstep with frequency 300Hz. I use stand still power saving, automatic torque and stall detection.

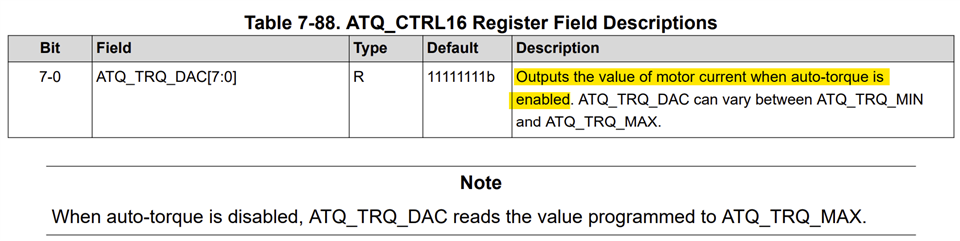

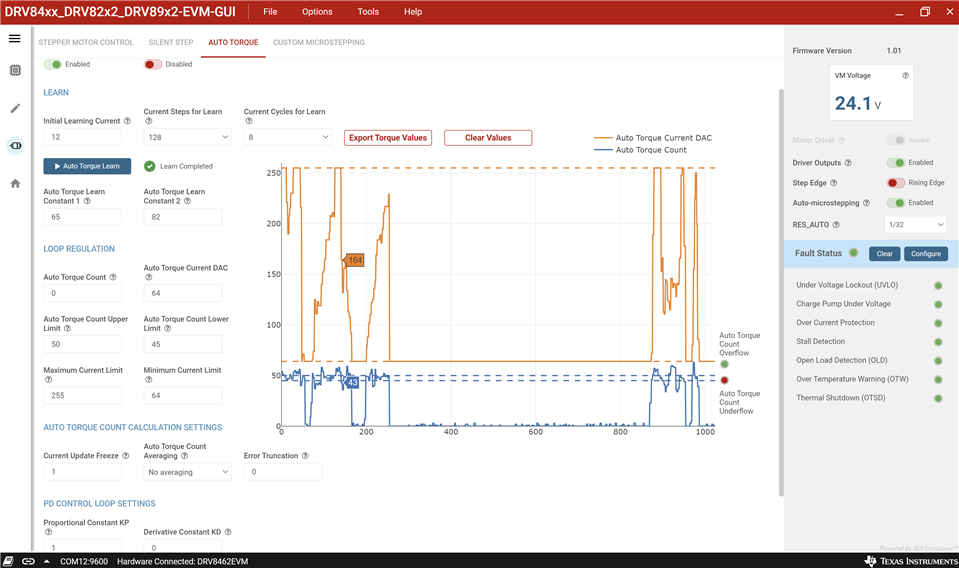

I am trying to read atq_trq_dac register during move of motor, but always value of this register is equal ATQ_TRQ_MAX, despite the fact that ATQ is enabled.

According to DS - "Outputs the value of motor current when auto-torque is enabled. ATQ_TRQ_DAC can vary between ATQ_TRQ_MIN and ATQ_TRQ_MAX."

- When auto-torque is disabled, ATQ_TRQ_DAC reads the value programmed to ATQ_TRQ_MAX.

When I am reading ATQ_EN (ATQ_CTRL10) is set "1" (auto torque is enabled).

For example atq_trq_min (ATQ_CTRL11) is set 15, atq_trq_max (ATQ_CTRL12) is set 70, and atq_trq_dac read is 70 too, for all move with different weight, when atq_cnt changes according to the moment of load.

I want to use atq_trq_dac to read the current at a given time, when I am using ATQ. Do I misunderstand atq_trq_dac_purpose?