Other Parts Discussed in Thread: DRV10970, , MCF8316A

Hello,

We are developing a product for an application that requires high control performance with low power. We aim to drive a PMSM (Permanent Magnet Synchronous Motor) in the speed range of -5000 to +5000 RPM using a speed controller while maintaining minimal jitter (less than 1 RPM). Precise speed control at low RPMs (e.g., 5 or 10 RPM) is crucial for our application.

Initially, we evaluated the DRV10970 motor driver, which offers sensored sinusoidal or trapezoidal control for 3-phase BLDC (Brushless DC) motors. The DRV10970 seemed ideal for our low-power application due to its lack of dependency on a C2000 microprocessor and its code-free operation. However, we later discovered that the DRV10970 restricts speeds below 10% PWM command (as indicated in the datasheet). Consequently, we cannot drive the motor below approximately 500 RPM using this driver.

As an alternative, we are considering the MCT8315Z motor driver. However, we are uncertain whether it will encounter issues at low speeds and whether it is compatible with our hall sensor placement. Additionally, while we prefer sinusoidal current for the PMSM, we can accept trapezoidal commutation if it allows operation at low RPMs. Could you please provide an evaluation of the MCT8315Z? Does it have a similar low-speed limitation like the DRV10970?

We also understand that sensorless motor drivers (such as the MCF8316A with field-oriented control) are not ideal for low RPMs due to their technology limitations.

Could you recommend an optimal motor driver and algorithm architecture? Ideally, we need a motor driver that accepts torque commands, performs its own current loop control, and operates reliably at low RPMs. We plan to implement the closed-loop speed controller on a separate board, where we can provide PWM or digital input commands. Additionally, we can incorporate an incremental encoder alongside the hall sensor.

Thank you in advance for your assistance.

Motor Specifications:

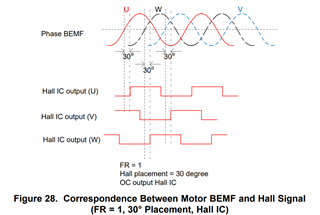

PMSM features: sinusoidal back electromotive force (bemf), 30-degree hall placement, and digital hall sensors, 12V nominal voltage, 7 pole-pairs, 0.66A rated current, phase-phase 6.95 ohm and 884 uH. If needed, we can provide further details.

Best regards,

Gokhan