Other Parts Discussed in Thread: MCF8316AEVM, MCF8316A

Tool/software:

Hi TI,

We plan to use MCF8316C-Q1 to driver some BLDC motor in limited range and limited time. I have already read the MCF8316C-Q1's datasheet., and it is a little complicated for me to understand...

My questions are as following, could you kindly help to analyze? Thanks a lot.

1.What is the MCF8316C-Q1's I2C address(Target ID)? I did not see the direct description in the datasheet, except the 0x60 in the example. So 0x60 is its unique target ID?

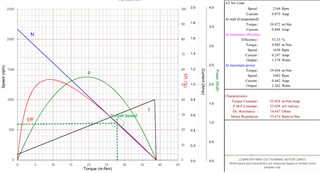

2.In our product, we have to finish the specific range in limited time such as 3 seconds, and the target speed is around 600RPM. Could this target speed be enough to generate enough BEMF for MCF8316 to recognize?(You could see the performance curve in the following)

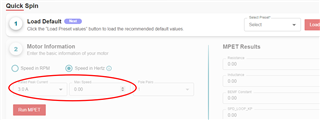

3.I have a MCF8316AEVM in hand. For the software Motor Studio(ver: 0.1.18), what should I set for the Ralated Peak Current and Max Speed?

(1)Ralated Peak Current parameter

In <MCF8316A Tuning Guide>, it said "Rated peak phase current is the peak phase current drawn by the motor at rated torque of the motor". The performance curve provided by the motor supplier is:

Our target speed is around 600RPM, which should be bigger than the rated torque, then the corresponding current should be bigger than Rated peak phase current. Which point should I choose to set its current value to Ralated Peak Current? Assume the current at rated torque of the motor was chosen, could we get the target speed 600RPM while the current was limmited by the rated current?

(2)Max Speed

Should this parameter set to our target speed 600RPM, or the no-load speed 2100RPM?

4.MPET related

(1)Are the MPET results the same for the motors of the same type from the same motor supplier? Need I to do MPET for every motor?

(2)Are the SPD_LOOP_KP/SPD_LOOP_KI constant? If I run MPET on the motor with no load, could the SPD_LOOP_KP/SPD_LOOP_KI got from this run used to the motor with load?

5.We would use another MCU to communicate with MCF8316Q-Q1 via I2C, so we could not directly use MSP430FR2355-GUI-FIRMWARE which is used for MCF8316AEVM. Writing the specfic values to so many registers seemed to be complicated and trivial. Is there some easy way to configure MCF8316Q-Q1 on another MCU?

6.In the DRV8889 which is Stepper Motor Driver, we implemented acceleration and deceleration strategy to get smooth start and stop. Is there any need to implemented acceleration and deceleration strategy on MCF8316? Or the only thing we do is set the target speed?

Thanks,

Alex